Cleaning Products Go Green

While most household cleaning categories limp along, products promoted for their environmental benefits are posting double-digit gains.

Tom BrannaEditorial DirectorIn the long run, environmentally friendly household cleaning products may be good for the planet, but in the short term, they’re even better for a company’s bottom line. Why else would Clorox roll out Green Works, Church & Dwight introduce Arm & Hammer Essentials or S.C. Johnson scoop up Caldrea? The chart below shows how category sales have slipped during the past year, yet according to Information Resources, Inc., sales of Mrs. Meyers’ Clean Day Tub & Tile Cleaner jumped 225% and Seventh Generation’s glass cleaner surged 220%. The benefits and challenges of going green in the cleaning category were brought to light in a recent conference, “What’s New on the Clean Green Scene,” held Nov. 18-19 in Alexandria, VA. The conference was developed by Intertech Pira in association with The Soap and Detergent Association. “Sales of conventional cleaning products have declined, but natural cleaning product sales have risen,” noted Martin H. Wolf, director, product and environmental technology, Seventh Generation. Mr. Wolf pointed out that according to a recent Gallup Poll, last year 80-90% of Americans recycled or reduced energy use, while 73% purchased environmentally friendly products. There’s no denying that green products are here to stay, but as conference chair Brian Sansoni, VP-communications, The Soap and Detergent Association noted, there is much confusion among consumers, lawmakers and even marketers of finished products. After all, the term “green” is simply a marketing term, with no scientific basis. “We have to develop a sustainability message and make it meaningful,” observed Mr. Sansoni. Not long ago, household product marketers could perform a bit of market research, add a new surfactant and maybe a fragrance and tell the consumer to take it or leave it; that’s not the case any more. Today, purchasers are driving demand. “It’s no longer, I make it, you take it,” explained Bill Balek, director of legislative affairs, International Sanitary Supply Association (ISSA).

The same is true within government, as state and federal procurement policies increasingly call for green cleaners. In fact, 16 states have already adopted green cleaning procurement policies and six more are getting ready to introduce their own policies. The good news for industry is that as more states adopt green cleaning standards, they are often based on existing policies, so marketers don’t have to face disparate guidelines. At the federal level, there has been much activity even under a Republican president. President George W. Bush signed Executive Order 13423 that calls for a green procurement policy. Although that Order hasn’t been finalized, Mr. Balek predicts even more activity when President-elect Barack Obama takes office. “If you sell to the government, and they want a green formulation, you have to supply it,” added Mr. Balek. “And that has an indirect impact on consumer demand.” At the same time, more non-government organizations (NGOs) are having an impact on cleaning. One of them, Healthy Schools Campaign (HSC), is a driving force on the issue. HSC recently held a National Summit in Washington DC called, Green Cleaning for Schools. Other prominent NGOs include Hospitals for a Healthy Environment and the U.S. Green Building Council (GBC). Mr. Balek noted that there are 15,000 buildings in the country waiting to be certified by the U.S. GBC, and that cleaning plays in an integral role in the certification process. In fact, it can account for as much as 40% of a company’s score in certification. Demands for green cleaners are coming from the U.S. Department of Agriculture (USDA) too. The Farm Security and Rural Investment Act calls for the use of bio-based cleaning products, which, according to USDA, are more benign. The Act impacts a wide range of products including bathroom cleaners, carpet and upholstery cleaners, floor strippers, glass cleaners, graffiti removers, hard surface cleaners and general purpose cleaners. Marketers interested in getting their products approved for use by the USDA, should contact the department immediately, according to Mr. Balek. “Green cleaning represents a small (5-10%) portion of the market now, but growth is very strong—even in a down economy,” he concluded.

Consumers’ AttitudesUnfortunately, in the consumer market, when the chips are down and budgets are stretched, the environment often takes a back seat to economic woes, according to Pamela Helms, vice president-research and development, The Caldrea Company. In fact, in one recent study, 75% of Americans put the economy ahead of the environment. Still, Ms. Helms said the green movement is here to stay, even if consumers are suffering from a bit of “green fatigue.”

Pamela Helms, The Caldrea CompanyIn a study to learn how green values and lifestyles intersect, Caldrea found that there are several “shades of green” among consumers. They include: • It Ain’t Easy Being Green: These consumers say being green is too much to think about; • Sheer Green Tulle: These consumers buy what they like and if it’s green, then that’s a bonus; • Envy Silk Green: These consumers hope others notice how green they are; • True Blue Green: These consumers do the right thing for their family (and that often means buying green products); and • Into the Forest Green: These consumers are advocates leading the green cause. But regardless of how many consumers fit into each category, Ms. Helms insisted that the green movement is gaining strength. In fact, in the future, she predicted that, in the future, the term “green” will become irrelevant because it will become a cost of entry into the cleaning segment.

Yeah, But What Is Green?Green may be here to stay, but no company, agency or NGO has created a widely-accepted definition of green. That lack of a definition creates confusion among suppliers, marketers and consumers. But David Long, a consultant to the American Chemical Society, suggested that companies can get started on the right path toward green by following the 12 Principles of Green Chemistry, which were first suggested by Paul Anastas and John Warner in their 1998 book, Green Chemistry: Theory and Practice. The 12 principles are: 1. Prevent waste: Design chemical syntheses to prevent waste, leaving no waste to treat or clean up. 2. Design safer chemicals and products: Design chemical products to be fully effective, yet have little or no toxicity. 3. Design less hazardous chemical syntheses: Design syntheses to use and generate substances with little or no toxicity to humans and the environment. 4. Use renewable feedstocks: Use raw materials and feedstocks that are renewable rather than depleting. Renewable feedstocks are often made from agricultural products or are the wastes of other processes; depleting feedstocks are made from fossil fuels (petroleum, natural gas, or coal) or are mined. 5. Use catalysts, not stoichiometric reagents: Minimize waste by using catalytic reactions. Catalysts are used in small amounts and can carry out a single reaction many times. They are preferable to stoichiometric reagents, which are used in excess and work only once. 6. Avoid chemical derivatives: Avoid using blocking or protecting groups or any temporary modifications if possible. Derivatives use additional reagents and generate waste. 7. Maximize atom economy: Design syntheses so that the final product contains the maximum proportion of the starting materials. There should be few, if any, wasted atoms. 8. Use safer solvents and reaction conditions: Avoid using solvents, separation agents, or other auxiliary chemicals. If these chemicals are necessary, use innocuous chemicals. 9. Increase energy efficiency: Run chemical reactions at ambient temperature and pressure whenever possible. 10. Design chemicals and products to degrade after use: Design chemical products to break down to innocuous substances after use so that they do not accumulate in the environment. 11. Analyze in real time to prevent pollution: Include in-process real-time monitoring and control during syntheses to minimize or eliminate the formation of byproducts. 12. Minimize the potential for accidents: Design chemicals and their forms (solid, liquid or gas) to minimize the potential for chemical accidents including explosions, fires and releases to the environment. “Green chemistry can solve many of our problems,” Mr. Long insisted. “But we have to do a better job of educating future chemists about green chemistry.” To promote the value of going green, earlier this year, The American Chemical Society formed a Formulators’ Roundtable to get the cleaning industry to start thinking about going green. Ultimately, the group plans to develop a definition of green that’s based on the 12 Principles of Green Chemistry. “Our mission is to drive companies to use green chemistry,” he told the audience. Lauren G. Heine, senior science advisor, Clean Production Action, observed that together, green chemistry and innovation reduces risks by reducing hazards. “We’re all starting to pull in the same direction in terms of sustainability,” observed Dr. Heine. “It wasn’t like that 10 years ago.” She provided details on the U.S. Environmental Protection Agency’s Design for the Environment (DfE) program. When a product carries the DfE logo, that means that a DfE technical workgroup has screened each ingredient in the product for potential human health and environmental effects and that, based on currently available information, predictive models and expert judgment, the product contains only those ingredients that pose the least concern among chemicals in their class. Formulators interested in these chemicals, can view some of them at www.cleangredients.com.

Packaging ConcernsConsumers, government agencies and NGOs may be driving the green movement, but for many marketers, the 800-pound gorilla in the room is Wal-Mart. The world’s largest retailer may represent as much as 40% of a company’s annual sales. So when Wal-Mart wants something you can bet that its suppliers high tail it to Bentonville, AR. And what Wal-Mart wants more than just about anything these days is to be green. To get there, the retailer has issued a packaging scorecard that includes more than 200 data points per SKU that its suppliers must fill out to be in compliance. The scorecard is focused on four key data points: Material type (what packaging materials are used); Material weight (how much of each material is used); Material distance (how far the packaging component traveled before being filled) and Packaging efficiency (how efficiently available space is utilized). The goal is to reduce packaging costs by 5%. And woe be to any supplier that tries to skirt the issue. “Nobody is getting a free pass on this initiative, although bigger companies are able to file their data electronically,” insisted Victor Bell of Environmental Packaging International. For now, Wal-Mart is most concerned with amassing data. (And mirroring its often strong-arm tactics, if data for the laundry category is 70% complete, but your company has entered only 30% of its data, you can bet that Wal-Mart executives will want to know why you’ve fallen behind.) Further down the road, the retailer will take a closer look at the data to see how its suppliers have reduced packaging—and how it can profit from the reductions. For example, if a company has cut 10 grams of aluminum from a can, Wal-Mart will want a percentage of that savings. In fact, the company has hired Bloomberg to get regular reports on commodity prices. Now, Wal-Mart is getting ready to launch a Sustainability Index that will include a product-by-product ranking of the products it sells. Wal-Mart will use the index to evaluate its 60,000 suppliers and the hundreds of thousands of products that end up on store shelves. According to the company, 90% of the sustainability impacts associated with Wal-Mart come from the products it sells. But no matter how green you think your product is, Janice Podol-Frankle, an attorney with the Federal Trade Commission, reminded the audience that product claims must be truthful and non-misleading and that companies must be able to substantiate all claims. To help marketers with their green claims, the Commission issued Green Guides in 1992 and updates them periodically with input from industry (see www.ftc.gov/green). The guides’ general principles include: use clear and prominent qualifications; be specific, make clear whether claims apply to product, package or a component of either; provide clear comparative claims and don’t overstate a product’s attributes. For example, any package that includes seals or certifications should provide an explanation of what they mean. If a product includes a biodegradability claim, it must degrade at the same rate (or faster) than sewage. If the FTC rules that advertisements are deceptive, it may issue a cease-and-desist order, demand refunds to consumers or even disgorge profits to the U.S. Treasury.

Michelle Radecki, SDAAccording to Michelle Radecki, SDA’s general counsel, SDA provided input when the guides were first developed and is actively engaged in their current review. For example, SDA has suggested the use of environmental seals and logos must be specific, qualified and substantiated and the criteria should be transparent and readily accessible. SDA said the guides should be updated to encourage marketers to engage in more lifecycle thinking. New claims to be considered for the guides, according to SDA, include “natural” and “naturally-derived,” “organic” and “sustainability.” “The SDA will continue to participate in the current review of the Guides,” concluded Ms. Radecki. “Once they’re revised, we’ll educate our members.”

SEE A SURVEY RESULTS ON GREEN MANUFACTURING IN THE USA @ http://www.putman.net/brands/cp/downloads/cp_sap_green_survey_summary.pdf

martes, 16 de diciembre de 2008

AGAIN "GOING GREEN' FROM HAPPY DEC

martes, 26 de agosto de 2008

HOW TO FORMULATE INSECT REPELLENT

An insect repellent is usually a liquid that is used on the skin or clothes to discourage the climbing or landing of insects like fleas, flies, mosquitoes and ticks on the surface.

Normally repellents work by masking carbon dioxide, lactic acid and sweat odors that are emitted by the human body and by having a specific scent that insects avoid.

The best proven chemical repellent is DEET ( N,N-Diethyl-m-toluamide; C12H17NO).

A concentration of 0.1 grams is enough to act on a 72 square inch area of skin.

Formulations are basically based on a 5 to 25 % concentration.

A typical formula contains: 10 % DEET, 40 % Alcohol, 0.5 % Carbomer, 48.5 % Water and 1 % of a 50% solution of TEA. Simply add the carbomer to the Alcohol and DEET and then add slowly the water and finally the TEA.

A natural repellent can be made by using Geranium oil, Citronella oil, Lemon Eucalyptus oil and also Vitamin E has proven to be effective in an oil suspension.

lunes, 18 de agosto de 2008

jueves, 26 de junio de 2008

REMEMBER GRIGNARD REAGENTS ??

Grignard reagents (R-Mg-X) are highly versatile tools for building carbon skeletons of complex organic molecules. While the chemistry of Grignard reagents has been known for over 100 years, their use in synthetic organic chemistry has never been more popular. As a producer of numerous specialty organic compounds, let us put our experience with Grignard reagents to work for you and your application!

Grignard Reagents are currently available from GFS Chemicals:

To use chart at right: Locate the desired 'R' (alkyl) group by row and halogen 'X' by column. The letters correspond to available solvents; T = tetrahydrofuran; E = diethyl ether.

As with all GFS Chemicals products, you'll enjoy the flexibility of being able to buy exactly how much material you need, from bottles to bulk – No more adapting your needs to the limitations of other suppliers' package offerings!

GFS Chemicals also carries a full line of anhydrous solvents suitable for Grignard systems, as well as materials for use as Grignard initiators:

Solvents: Ethyl ether, anhydrous (#916) Tetrahydrofuran (#2492) MTBE (#2268) n-butyl ether (#2639)

Initiators: cerium(III) chloride, anhydrous (#2902) iodine, prills (#2748)

miércoles, 25 de junio de 2008

WASTE CO2, A PROBLEM IN OUR TIMES

A great report can be read in the Chemical Processing magazine, June 08 edition (www.chemicalprocessing.com), describing an alternative use that can be given to waste carbon dioxide.

We are all conscious by now that CO2 levels in the atmosphere are constantly growing due to motor and industrial emissions amongst other causes; and that we have lesser trees and vegetation to convert it to oxygen.

Worst news about this is that the increase in CO2 content in the greenhouse gas composition, has a drastic increase in the temperature rise in the atmosphere with time, and is one cause for the global warming we are all worried about.

The good news is that scientists are working to find ways to use the excess CO2 being produced; like Dr. Michael North, a professor of organic chemistry and a group of researchers at the University of Newcastle, UK that believe have identified a role of the gas as feedstock. They have developed a method to convert waste and non purified CO2 into cyclic carbonates at ambient temperature and atmospheric pressure, using a highly active aluminum catalyst. Cyclic Carbonates find uses in application as solvents,paint strippers, biodegradable packaging and as a feedstock for anti-knock agents for gasoline.

lunes, 23 de junio de 2008

New pumping extractor to remove oil and grease from water

See at www.oilskimmers.com a list of units that will collect various volumes of oils (100+ gph) from water. It is very simple: there is a special Polyurethane rubber tube or belt that attracts oils, collects them and deposits them in a reservoir. Can work 24 hours and withstands temperatures up to 200 degrees F and freezing conditions.

New pumping extractor to remove oil and grease from water

sábado, 21 de junio de 2008

Ojo con los Zapatos de Goma

En la Universidad de Arizona el Dr Charles Gerba, un Microbiologo, investigando conteos de bacterias en objetos del hogar, ha encontrado que en promedio se pueden encontrar 421000 unidades de bacterias en la parte externa y 2887 en la parte interna de unos zapatos de goma.

En la Universidad de Arizona el Dr Charles Gerba, un Microbiologo, investigando conteos de bacterias en objetos del hogar, ha encontrado que en promedio se pueden encontrar 421000 unidades de bacterias en la parte externa y 2887 en la parte interna de unos zapatos de goma.

Algunas de estas bacterias encontradas incluyen Escherichia coli, causante de infecciones intestinales y del tracto urinario, diarrea; Klebsiella pneumonia, causante de pneumonia e infecciones circulatorias y Serratia ficaria causante de infecciones respiratorias, asma y otras.

Estas bacterias son causantes de muchas infecciones de la piel, hongos, pies de atleta y ademas son transmitidas de algunos pisos contaminados a otros pisos en el hogar.

La buena noticia es que solamente lavando los zapatos de goma con detergente reduce la cantidad de bacterias en un 90 %. El uso de antibacterianos en la parte interna de los zapatos resuelve el problema temporalmante pero no controla las bacterias externas. Para leer mas sobre este estudio vea www.rockport.com

Asi que a lavar los zapatos frecuentemente !!!

lunes, 16 de junio de 2008

PLASTICOS QUE PUEDEN RESISTIR LA PRESION

Es sabido que el Polietileno de Alta Densidad, (PEAD, HDPE en ingles) es uno de los plasticos mas economicos y mas utilizados, especialmente en la elaboracion de bolsas plasticas y envases plasticos, como en botellas para el envasado de productos de limpieza y quimicos en general.

Sin embargo una desventaja del uso del polietileno es la permeacion a vapores o gases, y su falta de claridad debido a su cristalinidad. Estas ultimas caracteristicas llevan al consumidor a utilizar envases de otros polimeros, como el PVC, Policarbonato o PET, que son transparentes y aguantan mas presion interna, pero a mucho mayor precio.

Ahora sin embargo se ha logrado una nueva linea de envases de Polietileno que combinando su mayor pureza, su reduccion del estado cristallino, estilizando su forma estructural y optimizando el peso de la botella, se ha logrado un envase que permite llenar productos quimicos con muy alta presion de vapor como el hidroxido de amonio, conocido como amoniaco. Para mas detalles ir a http://www.pvcc.com/ o puede leer la revista Packaging World de Junio 2008 en http://www.packworld.com/ .En el caso del Polipropileno, se ha logrado esta mejora en las caracteristicas de transparencia, reduciendo la cristalinidad mediante el uso de agentes nucleantes como acido benzoico y benzoato de sodio.

NUEVOS CAMBIOS

Estos polimeros termoplasticos en general son destinados en su mayoria a la fabricacion de empaques; solo en Europa se gastaron en el 2007 una cantidad igual a 54 Billones de Euros correspondientes a 18.2 millones de toneladas de estos materiales. Esto debido a la gran flexibilidad de caracteristicas de estos materiales, su versatilidad, su resistencia, su bajo costo, su facil procesamiento y transformacion, etc, que han hecho que desde su descubrimiento, los plasticos hayan crecido enormemente en su utilizacion y han suplantado el uso de muchos otros materiales.......Pero sin embargo hay siempre una desventaja; los plasticos son demasiado duraderos y poco degradables, o sea que si dejamos en la tierra una botella de polipropileno, tarda demasiado tiempo en degradarse y descomponerse a sus elementos elementares por efecto del oxigeno, microorganismos y el tiempo. Esto ha hecho que las grandes empresas y gobiernos de muchos paises, ( y especialmente por el motivo de la biodegradabilidad, el calentamiento global, las fuentes alternas de energia, etc) esten considerando nuevamente el uso de materiales clasicos como el vidrio, papel, biomateriales, fibras naturales, carton o metales, que son mucho mas reciclables (100%) y con mejor biodegradabilidad.

martes, 10 de junio de 2008

CLEVER BACTERIAS ARE FORMING BIOFILMS

New R&D projects by BASF and Harvard University scientists are directing efforts to determine how biofilms are formed and how they can be prevented.

Biofilms, are bacterial communities that form on a range of surfaces from water pipes to medical devices in hospital patients, that have come under the microscope because they are believed to be the cause of severe hospital-acquired infections, leading to thousands of death every year.

Biofilms are difficult to eradicate because the constituent cells are intrinsically more resistant to antimicrobials and biocides than individual cells of the same species growing as dispersed populations and may require antibiotic level of biochemicals to combat them. This studies will combine knowledge of biochemistry, chemistry, biology, physics and materials science. For further information you may see May 26th edition of www.ChemicalWeek.com .

NEWS IN THE INDUSTRY

In the raw materials distribution channel, UNIVAR is quickly settling down after the purchase of CHEMCENTRAL with its large solvent's business.

Big chemical company Degussa and TH Goldschmidt Ltd, the house of Tego chemicals has been absorbed by EVONIK.

ALBERDINGK BOLEY has bought a polymer division of MEAD WESTVACO resins.

FMC acquired some divisions of ISP and AKZO NOBEL purchased British ICI. This is a sad moment for the British Chemical Industry that see one of their pioneer companies greatest in the 1960's........disappear . Now however AKSO NOBEL is selling ICI divison of sealants and adhesives, and electronic material businesses part to HENKEL.

For a great web page see the new CPC AEROSCIENCE, the leader in private label aerosol manufacture.

Rohm and Haas completed the acquisition of the polymer dispersion division of FINNDISP, Finland.

Ashland has agreed to buy Hercules for $3.3 billion, valued at $23.01/share.

DOW ACQUIRES ROHM AND HAASDow, Midland, MI, and Rohm and Haas have announced a definitive agreement under which Dow will acquire all outstanding shares of Rohm and Haas common stock for $78 per share in cash. The acquisition of Rohm and Haas will make Dow the world's leading specialty chemicals and advanced materials company, combining the two organizations' best-in-class technologies, broad geographic reach and strong industry channels to create an outstanding business portfolio with significant growth opportunities.

Tomah3 was recently bought by Air Products...visit www.airproducts.com

domingo, 8 de junio de 2008

Phosphatizing Metals

Iron Phosphate Cleaner/Coaters

TrueFinish offers a wide variety of pretreatment products. Our Chemfos KA is a fluoride containing spray wand product. This product can be used on CRS (cold rolled steel), Aluminum, and Galvanized steel as well.

Chemfos KA is completely miscible with water and applied by the common steam gun apparatus or similar equipment. This product provides an iron phosphate coating weight of 20-60 milligrams per square foot.

Product Benefits:

Each product is biodegradable

All products are in liquid form (no slurry tanks needed)

Each product is easily dispersed in water

Cleaner/coater concentration can be controlled easily through metering system

Variety of products (6) to meet your cleaner/coater requirements

A cleaner/coater can be used with a hot, high pressure spray wand or in a 3-stage spray system

For more information on this or any of our other products please email us at truefinishsupport@ppg.com.

sábado, 7 de junio de 2008

QUIMICOS MUY UTILES PERO QUE PUEDEN SER TENTADORES Y NOCIVOS.....

En este articulo quiero mencionar especificamente el caso del Quimico, Dr. Albert Hofmann, un investigador suizo que trabajo para los Laboratorios Sandoz, que murio recientemente (Abril 08) a la edad de 102, 65 despues del descubrimiento del LSD.

Hofmann que estaba estudiando "los jugos gastrointestinales de los caracoles en los cultivos de uvas", que no era una gran eminencia ni una estrella como otros colegas como el Dr Timothy Leary de Harvard, dio a conocer al mundo una de las drogas que cambiarian mas notablemente el comportamiendo social y de estilo de vida de las personas. Prueba de esto es la moda psicodelica de esa fecha y la exteriorizacion de musicos como John Lennon, Jimmy Hendrix, Janis Joplin y otros que comenzaron sus "viajes" al espacio interno como psiconautas. Leary por otra parte hizo tambien experimentos subsecuentes con LSD como una droga psiquiatrica y se volvio loco tomando esta droga.

Hofmann tambien comenzo sus propios vuelos; despues del descubrimiento coincidencial del LSD en 1938, a partir de los alcaloides de los hongos Ergot , como tratamiento para los desordenes circulatorios, continuo los experimentos recristallizando estos alcaloides y observo que su percepcion y sentidos se veian afectados con solo oler estos compuestos. Hofmann en 1943, tomo una dosis de 0.25 mg de LSD y comenzo un viaje, con alucinaciones, modificaciones del audio, vision y de los sentidos en general, que para el, y como muchos lo describen fue el primer pason (bad trip) de la historia.

Hasta 1966 LSD fue legal en USA como una droga experimental, pero por el alarmante mal uso que muchos usuarios comenzaron a darle a la droga, fue declarada illegal en 1971 por Naciones Unidas para la mayoria del mundo. Hoy esta droga es utilizada por la medicina aplicada como un relajante y pasivante de las ansiedades en pacientes con enfermedades terminales.

martes, 3 de junio de 2008

LIMPIEZA CON HIELO SECO

Usted habra escuchado que la limpieza mas agresiva es la que se realiza en el proceso de "sand blasting", utilizado mucho por grandes contratistas para la remocion de pintura y oxido de grandes tuberias para gas o petroleo, o en la limpieza de piezas metalicas. Despues se empezo a utilizar el "soda blasting", utilizando bicarbonato de sodio granular como el medio de bombardeo. Hoy el nuevo metodo desarrollado es el uso de CO2, en forma de hielo seco granular que sublima de solido a gas, sin dejar residuo en la pieza que se esta limpiando. La accion ocurre al bombardear estas particulas de hielo seco a una alta presion sobre la superficie, produciendo microexplosiones que levantan el sucio, pintura, oxido y otros contaminates. Este proceso es muy efectivo, no es abrasivo a la superficie y no es toxico. Para ver mayores detalles de esta tecnologia, pueder revisar varios articulos en www.processcleaning.com edicion de mayo/junio 2008.

sábado, 31 de mayo de 2008

New Electrical Cleaner with no Chemicals !!

On Sanitary Maintenance magazine, may 08 edition, Tennant Co. announced their new ECH2O floor cleaner that electrically activates plain tap water, making it behave like a powerful detergent without any added chemicals. The cleaning effectiveness has no negative environmental impact and health issues associated with producing, packaging and transporting of traditional cleaning chemicals.

lunes, 26 de mayo de 2008

FISICO QUIMICA DE LAS FORMULACIONES QUIMICAS

La combinacion de diferentes materias primas o ingredientes de diferentes propiedades fisico-quimicas, para formar un producto con propiedades especificas definidas, se denomina la formulacion. La formulacion es el balance meticuloso de todos los ingredientes en una simple entidad fisica, que puede ser por ejemplo un liquido o solido. Usualmente debe existir una "quimica" entre los componentes para poderse obtener las deseadas caracteristicas del producto final; algunos componentes aportan las caracteristicas estructurales, como dureza, estado fisico, viscosidad, etc y otras las caracteristicas funcionalers, como color, lubricidad, solvencia, etc.

En muchos casos las caracteristicas de los componentes cambian su forma y fisico-quimica original, para dar paso a una nueva combinada: por ejemplo cuando se mezcla agua que es un liquido de baja viscosidad, con resina Xantan que es un polvo ligero, se obtiene una solucion de alta viscosidad que es muy homogenea y estable.

En fin, para establecer la correcta formulacion de cualquier producto, primero identifique las caracteristicas y propiedades deseadas para el producto, y luego seleccione las materias primas de acuerdo a sus caracteristicas fisico-quimicas que le puedan proporcionar las deseadas caracteristicas estructurales y funcionales, luego analice si hay "quimica entre ellas, para proceder luego a formularlas.

sábado, 24 de mayo de 2008

NEW PRESERVATIVES FOR TODAY's COSMETICS

Worst news is to realize that your wife's facial cream is not properly preserved and has a foul odor......or that a moisturizer cream has contaminated intensive care patients in a Barcelona's Hospital in Spain. Many new trends for the GREEN drive have put many chemists to work in big Chemical corporations. Traditional preservatives like Formaldehyde donors, Parabens and Isothiazolones have been put aside to give way to natural preservatives, which unfortunately are still not completely defined and not necessarily safe nor effective. Some companies are moving to preservative-free formulations by using actives of a particular class that have known antimicrobial activity like Lactylates or using some ionic surfactants and thickeners that require much less preservatives.

The new trend that seams to be working are the blends that still include Parabens that are believed to be the safest yet in terms of toxicological and use tests. These include products like Clariant's Nipaguard POB, phenoxy ethanol and piroctone olamine and benzoic acid and a second one POM, that combines the two first components with methyl paraben. Lonza's counterpart are Optiphen BSP and BSB which are also aromatics. For a complete report see www.happi.com may2008.

THE CHEMISTRY OF SKIN ACNE CARE

The skin is the largest organ of the human body. One of the most common problems of skin is ACNE, specially for ages between 10 to 15, for both male and females, even though males suffer it more. ACNE is caused by the increase in production of sex hormones (specially the male Androgen), which causes the sebaceous glands in the skin follicles to produce extra sebum that is charged into the hair follicles and eventually clogs the pores, together with the presence of dead skin cells, hair fragments and possibly bacteria.

With this identified, the treatment has to be a combination of preventive measures and the right chemical formulation. The chemical treatment combines a known bacterial killer such as Benzoyl Peroxide ( between 5 and 10%), that oxygenates the environment, combined with surfactants like Linear Alcohols and solvents like Propylene Glycol to dissolve and emulsify the sebum and the thickened vehicle like Xanthan gum to form the surface creamy film. Another Chemical treatment can be using Sulfur that kills bacteria by exfoliating the outer layer of dead skin.

For complete formulation go to http://www.happi.com/ may2008.

In the HAPPI magazine edition of June 2008, there is a report on the creation of cosmetic formulations for remediating Eczema and Dermatitis; the basic ingredients consist of Cetearyl alcohol and sodium cetearyl sulfate 15%, salicylic acid 0.4%, Menthol 0.3% and Water to balance.

This formulation will effectively control itch and pain.

miércoles, 21 de mayo de 2008

NEW GECKO ADHESIVE

It is a great discovery; this new adhesive, made of polypropylene microfibers, developed at the University of California at Berkeley, may be the closest man-made material to match the remarkable gecko toe hairs that allow the tiny lizard to scamper along vertical surfaces and ceilings. Two square centimeters of this material can hold 400 grams (0.88 pounds) weight, vertically bound to a smooth, clean, vertical surface. At the same time, the adhesive easily lifts off with minimal force, leaving no residue.

For a complete report, see Nano News, at www.pcimag.com , May 2008 issue.

martes, 20 de mayo de 2008

NEW CITRIC ACID CLEANER

International Products Corporation Introduces Micro® A07 Citric Acid Cleaner

Citric Acid Cleaner removes dirt without corroding surface.

May 16, 2008 - NSF-Registered for USDA A1 use, Micro® A07 Citric Acid Cleaner removes oxide, scale, mineral deposits, milkstone, and inorganic soils. Biodegradable blend of chelating citric acid and anionic surfactants has typical pH of 2.5 and zero-VOC, phosphate free, non-corrosive formulation. It carries no hazardous shipping regulations and can be used in CIP, ultrasonic bath, immersion, and mild agitation as well as filter membrane applications.

Burlington, New Jersey, USA: International Products Corporation (IPC) announces the launch of their new Micro® A07 Citric Acid Cleaner for removal of oxide, scale, mineral deposits, milkstone, and inorganic soils. This biodegradable blend of chelating citric acid and anionic surfactants offers enhanced cleaning performance compared to simple citric acids and other citric-based products. With a typical pH of 2.5, Micro A07 is milder than most acids, yet powerful enough to replace more aggressive acid cleaners. Micro A07 is used in CIP, ultrasonic bath, immersion, and mild agitation, and filter membrane applications. This cleaner is zero-VOC, phosphate free, non-corrosive, carries no hazardous shipping regulations, and is NSF-Registered for USDA A1 use.

Micro A07 complements IPC's current line of aqueous cleaners, which includes Micro-90® Concentrated Cleaning Solution a powerful alkaline cleaner for use in manual, ultrasonic, CIP, and low-agitation cleaning applications; LF2100® Liquid Low-Foam Cleaner, a high-performance alkaline cleaner for use in high-agitation washers and spray systems; Surface-Cleanse/930® Concentrated Neutral Cleaner, a nonionic, low-sodium detergent for electronic components and delicate metals; Zymit® Low-Foam Enzyme Cleaner, a neutral pH formulation of enzymes and detergents for removal of starches and proteins; and the newly introduced Zymit® Pro Enzyme Cleaner, a neutral pH formula of protease enzymes, detergents, and builders for removal of protein-based soils.

In addition, IPC manufactures and distributes P-80® Temporary Rubber Assembly Lubricants for improved assembly of low tolerance parts. The water-based lubricants provide safe, temporary lubrication during assembly, and then dry to allow a tight fit. P-80 lubricants are widely use in the automotive, appliance, and pump industries, and are compatible with most elastomers, plastics, and metals.

For more information, contact the manufacturer at 609-386-8770 or visit their website: www.ipcol.com. IPC is an ISO-Certified Company.

jueves, 15 de mayo de 2008

PEARLS FOR YOUR HAIR

NEWS FROM NYSCC

Cognis Launches Pearlizing Wax Dispersion

2008-05-14

A novel, mild pearlizer for personal care.

Cognis launched several new materials at the NYSCC Suppliers' Day show in Edison, NJ. For example, the company calls Euperlan Green the first green, ethylene oxide- and amine-free pearlizing wax dispersion. According to Cognis, this novel, tremendously mild and unique pearlizer enables formulators to create natural and attractive hair and body cleansing formulations. It is derived from natural sources, is easy to handle, and is liqud and cold processable, to help save production time and energy costs.Also new is Cosmedia ATH, an anionic liquid dispersion polymer that provides rheology control and facilitates the preparation of skin care emulsions. Supplied as an easily dispersed liquid, it can be used in either cold or hot process manufacturing and can be easily added at any stage of the manufacturing process without pH neutralization. It contributes to the suspension and stabilization of other ingredients because of its excellent thickening performance, according to Cognis.Finally, Cognis rolled out Cosmedia Gel CC, a new version of a hectorite dispersion with unique properties. It creates a homogeneous film on the skin and limits the sedimentation process of pigments in a final formulation—making it an excellent product for sun care, AP/Deo and color applications, according to the company.More info: www.cognis.com

POLYMERS

Polymers, by definition are entities of many parts. In chemistry they constitute the elemental molecule in most materials in the human body and the environment. Proteins, lipids, sugars, tissues are some examples of polymers in our body; in the environment, we can mention wood, wax, starch, crab and turtle covers, oils and greases and so on. Artificially or synthetically, we can produce near any kind of type and structured materials, starting with the appropriate "monomers" that are "polymerized" or linked together to a predetermined length to obtain the desired qualities and properties. Some examples of these are the plastic bags obtained from Polyethylene, a plastic bottle obtained from Polypropylene or a textile fibre obtained from a Polyester or a Polyamide like Nylon. Other examples are polyacrylates and polyurethanes used in floor care finishes and waxes or varnishes, adhesives and paints. For a general definition on polymers and more applications, go to www.adhesivesmag.com and look in the May 2008 issue.

martes, 13 de mayo de 2008

Peristaltic or Diaphragm Metering Pump ??

There can be as many definable parameters in a specific system as there are required functions. Although it would be impossible to identify all of them, the basic metering pump system parameters are: fluid, pressure, control capability and required maintenance. We can analyze each of these parameters with respect to a diaphragm and peristaltic metering pump system and compare their effect on the reliability of the overall system.

Suction strainer with check valve – typically includes a filter screen, valve body, check valve/ball, rubber seal/seat and a metal spring.

Suction tubing or piping.

Pump head with inlet/outlet valves – includes a pump head, valve bodies, check valve/balls, rubber seal/seats and (depending on the manufacturer) metal springs.

Discharge tubing or piping.

Injection fitting with check valve – typically includes a valve body, check valve/ball, rubber seal/seat and a metal spring.

Peristaltic pumps employ much fewer “wetted” components:

Suction tubing or piping.

Peristaltic pumping tube – typically includes inlet and outlet fittings.

Discharge tubing or piping.

Injection fitting with check valve – typically includes a valve body, check valve/ball, rubber seal/seat and a metal spring.

Both diaphragm and peristaltic metering pumps have proven themselves in a multitude of commercial, industrial and municipal chemical metering applications. Still, each pump type has its strengths and weaknesses. A quick review of the system parameter requirements can guide the user in selecting the best pump type for the specific application.

About the Author: Bill McDowell is a sales engineer with Blue-White Industries, of Huntington Beach, CA. With nearly 25 years at Blue-White Industries, he also has held positions as project engineer and engineering director. Contact: 714-893-8529, sales@blue-white.com or http://www.blue-white.com/

GREEN PACKAGING FOR SUSTAINABILITY COMPLIANCE

There's no doubt that a cultural shift is underway, a move towards saving the planet for future generations, and everyone is now striving to balance social environmental and economical concerns. While most are far from reaching a perfectly sustainable world, many companies and governmental institutions are making efforts in this directions. Sample of this is the replacement of plastic bags for paper bags in many cities and the use of materials such as hemp, recycled car tyres and organic cotton in the manufacture of shoes and purses. In the chemical world a lot of interest and effort is being placed towards the actual chemical ingredients in a formula, however the packaging is as important if not more since they are mostly plastics which have long environmental life. Now days many plastics, specially thermosetting are being substituted by aluminum or other more recyclable materials. Also many packaging are being produced from vegetable raw materials like the case of the developments from Nature Works that work from corn stock. For more details go to: http://www.natureworksllc.com/ . Also some companies like Wall Mart are requesting suppliers to meet criteria based on sustainability and recyclable parameters. For more information on green packaging see: http://www.beautypackaging.com/, April/May 2008 issue.

On this same line of events, the DuPont awards for packaging innovation in 2008 went GREEN, awarding a number of notable achievements in sustainable packaging. One of the distinguishable achievements was awarded to the "powerhouse" produce package of Kiwi fruit. The natural package is assembled with a vacuum-thermoformed tray made of fibers from a palm tree from Earthcycle Packaging that is overwrapped in a transparent film of regenerated cellulose from Innovia Films. To see more go to the May edition of www.packworld.com .

MRSA INFECTIONS AT SCHOOLS

Introduction

Methicillin-resistant Staphylococcus aureus (MRSA) infection is caused by Staphylococcus aureus bacteria — often called "staph." Decades ago, a strain of staph emerged in hospitals that was resistant to the broad-spectrum antibiotics commonly used to treat it. Dubbed methicillin-resistant Staphylococcus aureus (MRSA), it was one of the first germs to outwit all but the most powerful drugs. MRSA infection can be fatal.

Staph bacteria are normally found on the skin or in the nose of about one-third of the population. If you have staph on your skin or in your nose but aren't sick, you are said to be "colonized" but not infected with MRSA. Healthy people can be colonized with MRSA and have no ill effects. However, they can pass the germ to others.

Staph bacteria are generally harmless unless they enter the body through a cut or other wound, and even then they often cause only minor skin problems in healthy people. But in older adults and people who are ill or have weakened immune systems, ordinary staph infections can cause serious illness.

In the 1990s, a type of MRSA began showing up in the wider community. Today, that form of staph, known as community-associated MRSA, or CA-MRSA, is responsible for many serious skin and soft tissue infections and for a serious form of pneumonia. For more information go to:http://www.mayoclinic.com/health/mrsa/DS00735.

What type of infections does MRSA cause?

• In the community most MRSA infections are skin infections that may appear as pustules or boils which often are red, swollen, painful, or have pus or other drainage. These skin infections commonly occur at sites of visible skin trauma, such as cuts and abrasions, and areas of the body covered by hair (e.g., back of neck, groin, buttock, armpit, beard area of men).

• Almost all MRSA skin infections can be effectively treated by drainage of pus with or without antibiotics. More serious infections, such as pneumonia, bloodstream infections, or bone infections, are very rare in healthy people who get MRSA skin infections.

How is MRSA transmitted?

• MRSA is usually transmitted by direct skin-to-skin contact or contact with shared items or surfaces that have come into contact with someone else's infection (e.g., towels, used bandages).

What type of infections does MRSA cause?

• In the community most MRSA infections are skin infections that may appear as pustules or boils which often are red, swollen, painful, or have pus or other drainage. These skin infections commonly occur at sites of visible skin trauma, such as cuts and abrasions, and areas of the body covered by hair (e.g., back of neck, groin, buttock, armpit, beard area of men).

• Almost all MRSA skin infections can be effectively treated by drainage of pus with or without antibiotics. More serious infections, such as pneumonia, bloodstream infections, or bone infections, are very rare in healthy people who get MRSA skin infections.

Should schools close because of an MRSA infection?

• The decision to close a school for any communicable disease should be made by school officials in consultation with local and/or state public health officials. However, in most cases, it is not necessary to close schools because of an MRSA infection in a student. It is important to note that MRSA transmission can be prevented by simple measures such as hand hygiene and covering infections.

Should the school be closed to be cleaned or disinfected when an MRSA infection occurs?

• Covering infections will greatly reduce the risks of surfaces becoming contaminated with MRSA. In general it is not necessary to close schools to "disinfect" them when MRSA infections occur. MRSA skin infections are transmitted primarily by skin-to-skin contact and contact with surfaces that have come into contact with someone else's infection.

• When MRSA skin infections occur, cleaning and disinfection should be performed on surfaces that are likely to contact uncovered or poorly covered infections.

• Cleaning surfaces with detergent-based cleaners or Environmental Protection Agency (EPA)-registered disinfectants is effective at removing MRSA from the environment.

• It is important to read the instruction labels on all cleaners to make sure they are used safely and appropriately.

• Environmental cleaners and disinfectants should not be used to treat infections.

• The EPA provides a list of EPA-registered products effective against MRSA: http://epa.gov/oppad001/chemregindex.htm

lunes, 12 de mayo de 2008

WHAT IS THE HEALTH SITUATION FOR THE USE OF CHLORINATED SOLVENTS

Late toxicological studies and occupational hazard studies on Chlorinated solvents have placed most organic chlorinated hydrocarbons in the list of carcinogens. These chemicals are normally used in applications like:

- Dry cleaning operations

Fluorocarbon manufacture

Solvents for fats, oils, waxes, resins

Fire extinguishers

Organic synthesis

Polymer manufacture

Heat exchange medium

Chemical intermediate

Extraction of caffeine - Vapor degreasing

Parts cleaning

Engine cleaner

Degreasing agent

Cleaning printed circuit boards

Adhesives solvent

Aerosol propellant

Foam plastic blowing agents

Paint removers

Breathing small amounts of these solvents can cause headaches, lung irritation, dizziness, poor coordination and difficulty concentrating. Breathing or drinking large quantities of these solvents can cause impaired heart function, unconsciousness, long term kidney and liver damage and possibly death.

Please see the link http://www.meridianeng.com/chlorina.html for a complete list of properties and health facts for the most common chlorinated solvents.

Replacement for Hazardous or Chlorinated Solvents

Metalworking plants, metal service centers, fabricating, finishing facilities and rebuild shops should consider using PICO SOLV NPB to eliminate problems such as: residues in trapped areas, solvent fire hazards, rusting caused by water based cleaners, slow drying times and odor complaints. Typical applications include: oil removal from screw machined parts, dirty electrical components, oxygen service cleaning and coil-to-coil metal cleaning. PICO SOLV NPB is compatible with most metals, plastics and space-age materials and is inhibited against white metal staining and corrosion. If there is doubt about any material, users are encouraged to contact PICO's technical personnel.

PICO SOLV NPB does not contain petroleum solvents, chlorinated compounds, or water for improved health, safety and environmental compliance. PICO SOLV NPB is easily used in vapor degreasers, ultrasonic agitators, dip tanks, enclosed spraying systems or wiping. It is a stabilized azeotropic mixture that may be distilled many times and has good wetting characteristics to evenly coat surfaces, thus releasing its full power solvency to penetrate and dissolve oil and grease films.

jueves, 8 de mayo de 2008

CERA / WAX FOR POLISHING BOATS AND BOARDS

SHOULD YOU USE CHLORINE IN LIQUID, SOLID OR GAS FORM, WHEN TREATING WATER ??

Application Bulletin

Bulletin 3001

Cost Comparison

Chlorine Gas vs. Hypochlorite

Cost per pound of AVAILABLE CHLORINE:

Gas Chlorine - is 100% pure, elemental chlorine which maintains its strength indefinitely.

Average cost per pound is $0.45‡. Since it is pure chlorine, the cost per pound of AVAILABLE CHLORINE = $0.45/lb.

Powder Chlorine (Calcium Hypochlorite) - contains a maximum of 70% available chlorine.

Strength is rapidly lost in storage. Average cost per pound of powder chlorine is $1.23‡. Therefore, the cost per

pound of AVAILABLE CHLORINE = $1.76/lb.

Liquid Bleach (Sodium Hypochlorite) - contains approximately 10% † available chlorine.

Strength is rapidly lost in storage. Average cost per gallon is $1.29‡. One gallon weighs approximately 9 lbs. The

cost of 1 lb. of bleach is calculated at $1.29 / 9 = $0.143. At 10% strength the average cost per pound of

AVAILABLE CHLORINE is determined as $0.143 X 10 lbs. bleach = $1.43/lb

‡ Costs are average quotes from suppliers in Ft. Pierce, Florida metropolitan area, Nov. 1993. Costs may vary in

your area, but the relative differences in costs of the three types of chlorine tend to remain consistant.

† (Note: Most manufacturers of Sodium Hypochlorite will only guarantee a 10% chlorine strength in 16% solution,

due to loss of strength in shipment and storage.)

A study was carried on the use of these three alternatives on a base usage from 1 Lb to 100 Lb each day, between 100 and 350 days. The results for all of them showed that liquid bleach is the most expensive alternative, followed by the powder and having the gas as the much lower cost between them. However the use and dosage of gas can be very delicate and dangerous.

USE OF SILVER IN DISINFECTION

* New disinfectant ingredient silver ions: The new disinfectant silver ion ingredient featured in the figure above, is blended using Lion's proprietary technology which causes the mineral substance alumina silica to retain microparticulated silver ions on the surface. Just 15 nanometers in diameter or about one thousandth the size of typical silver particles, their microscopic size boosts disinfectant effectiveness, allowing them to fully penetrate and defend surfaces from bacteria.

martes, 6 de mayo de 2008

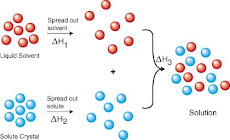

BASIC DEFINITIONS ON HOW TO MAKE EMULSIONS

When two liquids are immiscible but do not separate immediately they are said to form an emulsion. Some emulsions are quite stable and will take a long time to separate. For example milk is an emulsion of water and fat but is fairly stable. Other emulsions may separate quite quickly, for example a simple salad dressing of oil and vinegar will separate almost immediately (note that vinegar is water based).

The emulsion itself consists of small droplets of one liquid within the body of a second liquid. An emulsion containing droplets of oil in water is called an oil-in-water emulsion and the oil is called the dispersed phase while the water is called the continuous phase. An emulsion with droplets of water in oil is called a water-in-oil emulsion. A good oil-in-water emulsion will consist of very fine oil droplets homogeneously dispersed throughout the body of water.

Since colas are oil-in-water emulsions this discussion of emulsions assumes that an oil phase is being dispersed within a water phase. In practice neither the water phase nor the oil phase of an emulsion are likely to be pure substances. For example in colas the continuous water phase is an acidic solution of citric or phosphoric acid together with other ingredients such as caramel and sugar, the oil phase is a complex mixture of organic molecules from the essential oil flavourings. In general the water soluble molecules all stay in the water phase and the oil phase will be a mixture of all the liquid molecules that are not soluble in water (i.e. a mixture of oils).

FOR COMPLETE ARTICLE GO TO: http://sparror.cubecinema.com/cube/cola/chemistry/cola1.htm#top

lunes, 5 de mayo de 2008

MARBLE CARE AND CLEANING

The best way to remove stains on your natural stones surfaces, is to avoid them.

As a spill occurs, blot the spill with a paper towel immediately; do not wipe the area since it will spread the spill and potential stain. Flush the area with plain water and mild soap and rinse several times to completely remove spill. Dry the area thoroughly with a soft cloth. If the stain remains, then refer below to the procedure for stain removal that corresponds.

Stain Removal

The key to remove a stain from marble or stone, is to identify the type of stain. Investigate first as what caused the stain, where is it located, shape and color. Surface stain can often be removed by appropriate household cleaners; deeper stains that are absorbed or have penetrated the stone porous surface are more difficult to remove and may require an absorbent-solvent compound or a professional grade cleaner.

Cleaning Based on Stain Type

Oil or solvent based stains like cooking oil, motor oil, milky drinks, cosmetics,grease, tar and some inks, will darken the stone and normally must be dissolved so that the source of the stain can be flushed or rinsed away. This can be done by using one of the following: alcohol, mineral spirit, acetone or a butyl based degreaser. Simply apply on stain, allow to dissolve stain and clean gently with a soft cloth. Absorb as much as possible then rinse with a neutral cleaner and water.

Organic based stains like coffee, tea, fruit, tobacco, food, urine, leaves, bark, bird droppings all cause a pinkish-brown stain that in many cases will disappear if the source of the stain is removed as soon as it occurs; outdoors, with the source quickly removed, normal sun and rain action will generally bleach out the stains. In other cases and indoors, clean with a 12% Hydrogen Peroxide (hair bleaching strength) and a few drops of ammonia. Handle all chemicals with due care.

Metal oxides like iron oxides, rust and corrosion stains are orange to brown in color and follow the shape of the staining object such as nails, bolts and nuts, cans, metal furniture. Copper and bronze objects leave stains that are dark green-amber. These stains are very difficult to remove since they get embedded and adsorbed inside the stone's veins. The best way to remove them is using a paste (called poultice), made with an absorbent powder like kaolin or silica gel and a mild acid to clean the oxide. The poultice is spread on the stained surface with a spatula, covered with a plastic film and allowed to absorb the stain for at least 12-24 hours. This operation can be repeated if needed; however some deep stains may never be completely removed and sanding and buffing with steel wool may be necessary, followed by polishing or crystallization.

Biological or Organic stains, like mildew, mold, moss, algae, musk or fermented food residues can be removed using a solution of 1 cup of chlorine bleach or hydrogen peroxide in a gallon of water. You could also use the same dilution with an ammonia cleaner but this may have an unpleasant odor and is very harmful if it comes in contact with bleach.

Ink or Paint. Water based stains will be easily removed with a water based degreaser or a neutral cleaner. Oil based stains have to be removed with a solvent based paint stripper, acetone or lacquer thinner. Also use a wood or plastic scraper if necessary to remove stains. NEVER USE CAUSTIC PRODUCTS OR STRONG ACIDS TO REMOVE STAINS since they will damage or opaque the gloss of the stone and will require repolishing or recrystallization.

domingo, 4 de mayo de 2008

QUATERNARIES VS PHENOLICS AS DISINFECTANTS

QUATERNARIES

- Readily combine with non-ionic surfactants, making excellent cleaners since they are great detergents them self.

- They are water soluble.

- Work best at pH round 10, which is best for soap detergency.

- They provide high foam but also fast rinsing.

- Relatively safe to use, some are approved for use as topical and as no rinse sanitizers in food handling areas.

PHENOLICS

- Are inactivated by non-ionic surfactants, must be combined with anionic surfactants to formulate cleaners; these have lower cleaning power than non ionics .

- Do not solubilize in water, detergents are needed to suspend them in water, or alcohols to solubilize them.

- Maximal biocidal activity is achieved at pH of 6 to 7, when detergency is poor.

- Poor rinsing properties and residues left by anionic soaps makes inappropriate for floor cleaning.

- They have questioned safety for skin contact.

- They have greater residuality than quaternaries.

NATURAL BASED INGREDIENTS FOR PERSONAL CARE PRODUCTS

Organic, Green, Natural, all characteristics we would like to have for the chemical industry. Well, at least cosmetics and personal care products are closer. One example is the new line of Polyamides, which are family related to proteins in chemical structures, that are offered as thickeners in the formulations of Mascara, Sunscreen lotions, Anti-aging Lotions and Lipsticks. These low molecular weight Polymers are nature-based, skin-friendly, easy to incorporate can turn almost any liquid into a clear soft solid and allow the formation of emulsions with little or no surfactants. Actually some are lipophilic and therefore water repellent while some are hydrophilic and therefore water dispersible or water soluble. They provide enhanced gloss,a unique skin feel, insensitive to pH and electrically neutral. In general they are composed of polymeric chains formed by reaction of diamines with long chain di-acids, that can form tridimensional structures through Hydrogen bonding when in solution.

For more information see www.happi.com magazine, February 08 issue.

domingo, 27 de abril de 2008

OBTENGA REVISTAS TECNICAS GRATIS

Una gran cantidad de revistas tecnicas son publicadas periodicamente por Trade Publications y pueden ser obtenidas gratis. Para suscribirse, vaya a: http://www.tradepub.com/ y seleccione la que le interese. Llenar la solicitud es facil y al ser aprobado, recibira la publicacion por correo electronico e inclusive noticias semanales en los topicos seleccionados.S

FREE SUBSCRIPTIONS AT WWW.TRADEPUB.COM ALSO GET SANITARY MAINTENANCE AT WWW.TRADEPRESS.COM/SMSUB .

sábado, 26 de abril de 2008

"GREEN" VS "NATURAL" CHEMICAL PRODUCTS

It has been known that there is a great difference in the market between "organic" and common vegetables; specially in price!! But what is really an organic or totally natural vegetable, and how is this related to chemical products??

Well by definition a totally natural material is one that has not been contaminated or transformed by any additive or process derived from human source. So if an apple is washed with soap, or washed with chlorinated water, or waxed, is then not natural and if it is collected and processed by a machine, then it is not natural by definition. So if a natural soap which is derived from coconut oils, oleic acid, glycerin and soda is reacted in a reactor and finally filtered, then would not be considered natural. I think that is not fare; since we should really qualify them as natural based on their biodegradability and their re utilization potential, in addition to the safety of use that they represent

Another great topic of concern is the use of "green bio-fuel".

It is known that everybody is now concerned with the environment and the reduction on the use of synthetic and hazardous materials, via the formulation of chemicals that will not harm the environment and are safer to use.

See constant issues and advances on this topics in http://www.icis.com/blogs/green-chemicals/ and in www.icis.com/blog for advances in chemical news. In the April 2008 issue of the publication HAPPI, see at: www.happi.com, we can see the advantages and disadvantages of the use of renewable resources as crops and other vegetables, as a substitute for hydrocarbons derived from the petrochemical industry; also the resolution of some big chains like Wall-Mart are requesting their supplier to provide green products.

The final concern is that even though the use of bio-fuels is practically a need due to lowering availability of oil with time, and its negative effect on the environment, also is very true that the use of crops will reduce its availability for human and animal nutrition and will also require more energy feed to transform them in alcohols or other fuel additives.There has also been concern on the volatile emissions of these bio-fuels into the environment, once they are used as fuel.

One thing seams to be true and this is that there will be no cost reduction on the use of crops as alternative fuel feeds. Methanol from garbage digestion seams to be a good alternative but is less viable due to the extent of conversion and efficiency.

Please feel free to write your comments.

miércoles, 23 de abril de 2008

Amonios Quaternarios Vs Compuestos Fenolicos como Desinfectantes

Los compuestos Cuaternarios tan pronto entran en contacto con las celulas de las bacterias, entran a travez de las paredes celulares por osmosis. Los Cuaternarios interrumpen el proceso metabolico, matando asi la celula bacteriana. En cambio los compuestos Fenolicos son mas extremos en su actuacion; entran en la celula bacteriana, lesionandola e hinchandola a tal extremo que la revientan. Los Quaternarios son residuales en superficies duras, pero los Fenolicos son aun mas; es sin embargo dificil determinar la longitud de la residualidad de ambos y eso dependera de las condiciones del ambiente. Los Fenolicos son agentes Anti-Tubercolosis por excelencia, aunque hay formulas con Quaternarios que tambien se usan para tal fin. Desfavorablemente, los Fenolicos son mas toxicos que los Quaternarios y son mas caros. Ademas los Quaternarios son solubles en agua y los Fenolicos no, haciendo que los Quaternarios sean mas utiles en formulaciones de limpiadores desinfectantes base agua.

Vistas de página en total

GREEN CHEMICALS

Also the materials have to meet with toxicity and health requirements regarding inhalation, dermal and eye contact. There is also a specific list of materials that are prohibited or restricted from formulations, like ozone-depleting compounds and alkylphenol ethoxylates amongst others. Please go to http://www.greenseal.com/ for complete information on their requirements.

For information on current issues regarding green chemicals, see the blog from the Journalist Doris De Guzman, in the ICIS at: http://www.icis.com/blogs/green-chemicals/.

Certification is an important — and confusing — aspect of green cleaning. Third-party certification is available for products that meet standards set by Green Seal, EcoLogo, Energy Star, the Carpet & Rug Institute and others.

Manufacturers can also hire independent labs to determine whether a product is environmentally preferable and then place the manufacturer’s own eco-logo on the product; this is called self-certification. Finally, some manufacturers label a product with words like “sustainable,” “green,” or “earth friendly” without any third-party verification.

“The fact that there is not a single authoritative standard to go by adds to the confusion,” says Steven L. Mack M.Ed., director of buildings and grounds service for Ohio University, Athens, Ohio.

In www.happi.com of June 2008 edition, there is a report of Natural formulating markets that also emphasises the fact that registration of "green formulas" is very confused at present, due to lack of direction and unification of criteria and that some governmental instittion (in my opinion the EPA) should take part in this very important issue.