The effects of humidity on the drying and performance of a floor finish is very important. High humidity retards the evaporation of water from the polish film, leaving the film soft, incompletely dry, and very Scuffable. Floor finish films, like latex paints, dry (harden) from the surface inward towards the flooring. Thus a floor finish which appears to be dry and feels dry to touch can in fact be wet and soft down close to the floor. Adequate ventilation during and after applying a floor finish is very important. If the air in the area being finished is high in humidity, close the windows and run the air conditioner to lower the humidity. In the winter, turn up the heat to dry the air and also warm-up the substrate (flooring). Problems caused by high humidity are: Another important aspect in the drying of floor finish is the correlation between drying time and solids of the finish. Higher solids results in a thicker film developing on the floor and thus, a greater period of dry time being required between coats (sometimes in excess of one hour).

1. Excessive scuffing and black marking from traffic until finish dries hard.

2. Poor detergent and water resistance due to the delay in finish cross-linking.

3. The threat and reality of “gluing” furniture to the floor.

4. Streaking and mop drag created by the coat being applied “biting” into preceding coats. (this phenomenon is caused by the applied coat re-emulsifying the previous coating that has not yet cure.)

jueves, 10 de diciembre de 2009

EFFECT OF HUMIDITY WHEN APLLYING FLOOR FINISH

jueves, 3 de diciembre de 2009

LAS BONDADES DEL MAGNESIO PARA LA SALUD

MAS INFORMACION DE CLORURO DE MAGNESIO

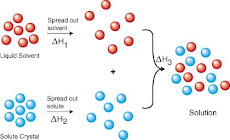

Cloruro y magnesio (Cl y Mg): Éstos son otros dos importantes elementos de la sangre. El cloruro es particularmente importante para regular el equilibrio de líquidos en el organismo. El magnesio se encarga de las contracciones musculares y de sintetizar las proteínas.

El magnesio tiene múltiples acciones beneficiosas sobre el organismo. Se le puede considerar toda una defensa ya que contribuye a depurar la sangre, disolver los depósitos de colesterol de los vasos sanguíneos, activar y movilizar los leucocitos, y a favorecer la producción de anticuerpos,..

El magnesio es un metal divalente del grupo alcalino-térreo, que ocupa el sexto lugar en abundancia natural entre los elementos de la corteza terrestre. Aparece en combinación química con otros elementos, en particular, en los minerales carnalita, dolomita y magnesita, en muchos silicatos constituyentes de rocas y como sales, por ejemplo el cloruro de magnesio, que se encuentra en el mar y en los lagos salinos.

Es, además, un componente esencial del tejido animal y vegetal ya que está presente en todas las células; lo que explica su presencia en nuestra alimentación. El magnesio capta la energía solar y la potencia, formando compuestos químicos que los organismos son después capaces de sintetizar. Al mismo tiempo, permite liberar el oxígeno necesario para las funciones respiratorias.

Anti-estrés

La mitad del magnesio de nuestro organismo se encuentra en los huesos, y la otra mitad está implicada en procesos celulares, realmente importantes. Toma parte en el mantenimiento de la glucosa y otras partículas nutrientes, para que posteriormente se pueda aprovechar la energía de éstas.

Entre las principales funciones y propiedades del magnesio hay que destacar la activación de vitaminas, enzimas, la formación de estructuras óseas y dentales, proteínas y anticuerpos, el mantenimiento de la viscosidad del líquido sinovial y la ayuda en el metabolismo de síntesis de los lípidos. Además, tiene una misión anti-estrés, antitrombótica, antiinflamatoria y cardioprotectora.

Sin magnesio...

La falta de este mineral hace que los reflejos nerviosos y musculares se deterioren. Su carencia conlleva, además, vértigos, convulsiones y debilidad en los huesos, puesto que su presencia en ellos es muy importante. La escasez de magnesio está relacionada también con el aumento de la tasa de potasio.

Corregir las carencias

Cuando hay una carencia de magnesio en el organismo, ésta se puede corregir administrando diariamente magnesio

Es bueno para prevenir las enfermedades infantiles como la rubéola, sarampión, faringitis, viruela, tos ferina, alergia y en general todas las enfermedades que cursan con fiebre o inflamación.

Es muy bueno para prevenir las migrañas.

Es excelente para evitar la pérdida de audición que se produce por la exposición a ruidos más fuertes que los normales.

Es bueno para las embarazadas porque ayuda para disminuir la presión arterial. También es bueno para el dolor menstrual y otros síntomas que acompañan a la menstruación.

Sirve de broncodilatador pues relaja los músculos que rodean los bronquios y dicen que ha sido utilizado con éxito en ataque agudos de asma bronquial.

Reduce el riesgo de cálculos renales porque aumenta la solubilidad del calcio en la orina.

miércoles, 2 de diciembre de 2009

THE GREAT VERSATILITY OF POLYURETHANE EMULSIONS

Innovation formulas from Bayer.

The aqueous 1K polyurethane dispersion solution for all indoor wood and glass coatings

Bayhydrol® UH 2593/1 is a unique binder that adds value to your formulations for parquet, furniture, joinery and glass coatings. Durability, drying speed andappearance are the attributes that describe the product best.The ecological, green label is not only because it is a solvent free aliphatic polyurethane dispersion, but it is also based on renewable resources - fatty acids. The latter undergo self crosslinking properties eventually leading to its high performance.

In Parquet Coatings:

Bayhydrol® UH 2593/1 provides very high black heel mar resistance (BHMR) and surface hardness. The transparency, wood warmth and gloss make the product particularly interesting for formulating glossy coatings. The easiness of downglossing and the fast drying lead to excellent semigloss and matt finishes.

Crosslinking with Bayhydur® 305 increases coating resistance while keeping the excellent transparency and wood warmth. Bayhydrol® AH XP 2741 is the first choice for PAC blending due to the high compatibility.

Get Technical Assistanceon coatings formulations containing polyurethane dispersions.

In Furniture Coatings:

Bayhydrol® UH 2593/1 brings high blocking resistance and scratch resistance to the coating. Therefore it's an interesting partner for blending with acrylic dispersions in 1K-WB coatings. Stain blocking is excellent, so it's an ideal choice for formulating 1K clear primers. The fast drying and high transparency are the advantages of Bayhydrol® UH 2593/1 as blending partner in the 2K-WB coatings (see graphs below). Very promising results are achieved also in waterbased UV-curing coatings, where the addition of Bayhydrol® UH 2593/1 to the polyurethane dispersion for UV curing improves the water releaseof the coatings and reduces the white pores effect significantly.

lunes, 23 de noviembre de 2009

NEWS AND FUTURE TRENDS IN HOME FRAGRANT AIR FRESHENERS

This article was taken from a publication on September 2009 edition, of HAPPI Magazine:

House guests with a spray of fragrance is said to be a Mediterranean tradition. And why shouldn’t it be commonplace in every home? Domestic scenting products are classically known as affordable, easy ways to provide a put-together and pleasant environment in a jiffy. A quick spritz of a lemon spray or lighting a lavender candle can work wonders in eliminating unsavory odors—even providing an aromatherapy boost to boot. Despite the benefits and in correlation with the recession of 2009, there has been a significant downshift in the home fragrance market. Total sales of the category, which includes home air fresheners and candles, fell 11% to $1.5 billion for the year ended July 12, 2009 in supermarkets, drugstores and mass-market retailers excluding Wal-Mart, according to Information Resources, Inc. (IRI), a Chicago-based market research firm. Super brands like Glade and Febreze still lead in both the air freshener and candle sectors, proving that shoppers are still trudging to mass-market stores for their home fragrance staples such as plug-ins, sprays and luminaries—but at a selective pace.While there have been a few glimmers of hope, the bleak economy in general continues to take a toll on the consumer products industry, noted Karen Doskow, associate project manager, Kline & Company, Little Falls, NJ. However, despite lackluster sales during the past year, the home fragrance market is well positioned to capitalize on the fact that, for a variety of reasons, consumers are spending more time at home.“To make the most of a tough situation, home fragrance marketers must retrench, reinvent and rethink their product development, distribution and marketing strategies in order to provide the kind of innovative products at an affordable price that consumers demand at this time,” noted Ms. Doskow. “Certainly, innovative delivery systems, repackaging and other product-centric innovations are a consideration, but marketers must also consider how and where consumers can access their products.”

Candles Light it UpHome fragrance is not only about scent; its design element is also imperative in creating a successful product, noted Simon Kneen, creative director, Banana Republic. He told Happi,“Candles in beautiful frosted or colored votives provide a sophisticated accent to any room. Home fragrance that looks great or has a strong architectural/design aesthetic has been successful in the past and will continue to be so in the future.”

An upscale room spray from Febreze for Fall 2009.Signature perfumes and colognes act as inspirations to the home fragrance market too, according to Mr. Kneen. For Fall 2009, Banana Republic is bringing back its popular Classic perfume in candle form. The top opens with juicy, sparkling notes of grapefruit zest and mandarin citrus, as the heart marries classic floral notes of lavender and exotic syringa flower with leafy silver sage. It dries down to blonde woods and musk—just as the eau de parfum (EDP). Marketers are also targeting the upscale consumer through mass to catch that shopper at an affordable price point. SC Johnson recently rolled out The Fragrance Collection by Glade, a line of gourmet-inspired candles available in scents such as lotus bamboo and acai. Meanwhile, Procter & Gamble launched the Febreze Home Collection, the brand’s first contemporary-scented and styled home décor line. The cornerstone of the collection is the Febreze Flameless Luminary. Its scented “shades styles,” as they are called, are available in fragrances such as pomegranate mango or green tea citrus. A wooden base activates a flickering, flameless glow and diffuses scents into the air via the shade. Seasonal offerings include cranberry pear, caramel crisp, orchard cider and vanilla frost.In addition to the Flameless Luminaries, the Febreze Home Collection offers the first soy blend candle for the brand, encased in glass with a bamboo base, as well as a room spray.“Over the past year, we have seen consumers continue to experiment with new air care product forms and scents in their homes,” said Cathy Beros, senior scientist, Febreze Home Collection Research & Development, Cincinnati, OH. “Consumers are enthusiastic about air care products that have a decorative design that will complement their décor.”Designs aside, sometimes it’s the scent that really makes a home fragrance product stand out, according to Rick Ruffolo, senior vice president of brand, marketing and innovation, The Yankee Candle Company, South Deerfield, MA. He tells Happi, “Without question, scented candles remain the single most popular way to enjoy home fragrance. When done right, scented candles make great gifts, are decorative and provide ambiance that other home fragrance devices can never match.”

Seasonal offerings from Chesapeake Bay Candle for Holiday 2009.In 2009, Yankee Candle’s best selling new fragrance introductions included Garden Sweet Pea, Lavender Vanilla and MacIntosh Spice. Mr. Ruffolo attributes his company’s success in the category to “seasonal relevance.”“We continue to see the importance of having the right scents at the right times of year. For instance, the food/spice category grows in importance and relevance as customers emotionally prepare for the Fall and Holiday seasons. Likewise, floral scents in the Spring, and fruit fragrances in the late Spring/Summer are ways for customers to integrate what’s going on in nature with the changing seasons into their homes,” he said. Mei Xu, owner/president of Chesapeake Bay Candle, Rockville, MD, agrees that a classic jar candle might just be the panacea for recessonistas craving a wallet-friendly new home fragrance item.“Value has been one of the strongest purchase decision drivers, and we have seen consumers trade down to more affordable candle and home fragrance solutions,” she told Happi. “Pillar candles and jars have regained popularity, as they allow consumers to combine décor and fragrance.”

The S-Pod from PartyLite.For Holiday 2009, Chesapeake Bay Candle will unveil a limited edition featuring “multi-note scents” of wild ginger cassis, Siberian fir pomander and black star anis in fragranced soy candles or reed diffusers. The candles are contained in a special edition silver mercury glass featuring the brand’s signature tree motif in clear glass—allowing the glow of the candlelight to shine through the mercury vessel. Items are wrapped in a gift box featuring silhouettes of blossoming trees spread over silver foil paper with ombre shading.

Sticks and Stones...and SpraysBesides the classic scented candle, air fresheners such as plug-ins or sprays are no longer just for the bathroom or kitchen. They have also become an important part of a home’s décor, noted market research firm Mintel.Due to their expanding role in the home, air fresheners are also appealing to varied demographics. Teenagers and homeowners who want to extend fragrance to more rooms than before are all being targeted, said Mintel in its report. Therefore, the top companies in the home air freshener segment are competing for the next best delivery system and are trying to keep up with the latest fragrance trends. While there is likely to be an increased focus on the home during the recession, air fresheners are discretionary purchases and will likely be one of those markets where consumers will look for better deals and may be more likely to purchase at mass merchandiser/discount stores, according to Mintel’s recent report on the market. Revamped delivery systems add decorative appeal to the product with aesthetic beauty, agreed Kline in its analysis. For example, Henkel’s Renuzit line has been reinvigorated with a modernizing spa-inspired upgrade to its familiar adjustable cone, including customizable wrappers that can be downloaded and printed for a personal touch to fit any decor. Further bolstering this steadfast brand, Henkel recently launched Crystal Elements, a set of scent-infused crystals in variations such as emerald rainforest or ruby berries, displayed in a decorative glass container. Portability is a big trend this season in home fragrance. Blyth’s PartyLite brand is building its client base with its new “fragrance on the go,” the S-Pod. Targeting all those smelly cars, purses, lockers, teenager rooms and offices out there, this travel-friendly scent device was designed to refresh anytime, anywhere and resembles an Apple iPod. It is available in four fragrances—French vanilla, strawberry fields, mulberry and calm waters—and is sold with a refill. Aura Cacia, a company that specializes in eco-friendly essential oils, is bringing spa-like benefits to the home with its new Aromatherapy Shower Tablets. The products are made with 100% organic essential oils and are available in lavender, eucalyptus or peppermint. The company also recently released a line of natural plug-ins. This collection of electric aromatherapy air fresheners features 100% pure essential oils to provide fragrance. The line is available in four aromas—lavender, lime and grapefruit, bergamot and orange and spices and clove.Fragrance sticks, or reed diffusers, are another popular delivery system for home fragrance. The natural wood gently draws the fragrance from essential oils usually housed in a glass jar into the air and gently evaporates into the surrounding room creating a long-lasting fragrance. Every couple of days, if the sticks get a little dry, simply turn them upside down and a fresh wave of fragrance will waft on by.Boutique brands such as Sweet Grass Farm, Greenland, NH, have found success in fragrance sticks. According to the company, these “unique and practical fragrance sticks” can be set up on a shelf, or in a powder room or bedroom. The company recently added ripe melon and citrus blossom fragrances to its roster of reed diffuser offerings; the company also will release a herb blossom linen spray and dusting oil for furniture outside of the wood stick range this season.Some marketers are focusing on glass jars that house the essential oils as ways to draw attention to their home fragrance collections. L’Occitane en Provence, a French body and skin care line, sells a line of reed diffuser sets inspired by the ink pots once used by schoolchildren.

Home Fragrance of the FutureWith most leading economists forecasting a weak recovery, there is still plenty of opportunity for home fragrance marketers to gain a foothold now and gear up for the future, noted Ms. Doskow of Kline. Retail sales of air care products are projected to increase by 12% between 2008-2013, according to Euromonitor International. One category that is expected to grow is electric air fresheners, such as plugs-ins, which may rise 3% between 2008 and 2013. Increasing commoditization is likely to lead to declines for gel air fresheners and other household air care, according to the report. Alyce Nicholsonsheehan, senior scientist, air care scent trends expert, P&G, sees the shift start with innovative new home fragrance variations. She told Happi, “Looking forward and with the economy in the doldrums, air care needs to catch a fresh new wind and breathe new life into our sails. I expect we’ll start to see some new scent notes within air care. Look for chic, feminine notes along with everyday, rugged masculine notes to be part of the fresh new beginnings.“While fruit notes and floral notes will always be part of the air care landscape, the passion will come from pushing the extremes of femininity and masculinity into new directions for air care,” she concluded.Ms. Xu at Chesapeake Candle agreed. “As far as fragrance trends are concerned, the most important trend for 2010 will be gourmand. Gourmand fragrances address the comfort trend—during these challenging times, people are seeking comfort to help confront daily financial and emotional stress.”Industry experts agree that this year, innovation and a little blood, sweat and tears could feasibly turn the home fragrance sector around. According to Ms. Doskow, “No doubt it will be a slow and steady climb, but the market is ripe for the leading consumer products companies to crank up the R&D engine and bring forth the next generation of home fragrance products. In this economy, it will take some landmark product and distribution initiatives to restore the market to the comfortable sales levels of its heyday.”

SIMPLE ASPECTS OF SHAMPOO FORMULATIONS

For the beginning cosmetic chemist, here’s a primer of the science, art and the secret tricks of the trade to create great hair shampoo, body wash and hand soap. The Formulation Basics for Personal Cleansers, is presented here as a very simple but complete base to formulate Personal care shampoos and is reported by Shoaib Arif Pilot Chemical Co.Cincinnati, OH.

(Disclaimer: The information contained herein is provided in good faith as starting guidelines to formulators and is based on the study in our laboratories and work of others. Pilot Chemical Company makes no warranties, expressed or implied, as to the accuracy of the information contained herein. Nothing contained herein grants or extends a license or permission in connection with patents of Pilot Chemical Company or others).

The ingredients used in a personal cleansing product, such as hair shampoo, body wash and hand soap, can be divided into four major categories: Primary surfactants, secondary surfactants, specialty ingredients and minor ingredients. This article examines each category and provides formulating tips to help the beginning cosmetic chemist create functional, yet aesthetically-pleasing products.Primary surfactants perform two important functions—cleansing and foaming. Desirable personal cleanser properties may also include quick and easy miscibility with water; instant flash foaming; nice, creamy lather that feels silky soft upon application, effective cleaning of soils from the hair and/or skin, quick and easy rinseability,and soft and silky afterfeel. Alkyl sulfates and alkyl ether sulfates such as sodium/ammonium lauryl sulfates and sodium/ammonium laureth sulfates, are cost-effective primary surfactants which are used in many personal cleansing applications. Alkyl sulfates and alkyl ether sulfates meet consumer demand for foam and lather as well as cleansing. These reasonably priced, high foaming surfactants have excellent cleansing properties. Most formulators prefer to use a combination of lauryl sulfate and lauryl ether sulfate. Lauryl sulfates produce creamier foam with higher volumes of small bubbles compared to ether sulfates. Conversely, ether sulfates, particularly the two and three moles (EO), produce better flash foam. To develop a product with optimum yet balanced lather profile, lauryl and lauryl ether sulfates are added in a certain range of ratios. For sodium lauryl sulfate and sodium laureth-2 sulfate a good starting ratio is 3:7 on an active surfactant amount basis. This combination of lauryl and laureth sulfate will give a nice, well-balanced lather profile that the consumer expects from a personal cleanser. This ratio is also a good starting point for viscosity response and short flow (non stringy) properties of the final product. Ammonium lauryl/laureth sulfates may be slightly better than their sodium counterparts in amount of foam generated, clarity at lower temperatures and viscosity response in certain formulas but they can release ammonia at higher pH. Some of the attributes that secondary surfactants impart to a formula include increased viscosity, stabilized foam and reduced skin and eye irritation. Personal cleansing systems based on alkyl sulfates and alkyl ether sulfates are relatively easy and cost effective for viscosity buildup. Generally speaking, a 10% active sulfate system will require about 1-2% of alkanolamide and 1-3% sodium chloride to reach or exceed a viscosity of 10,000 cps. Regarding rheology, this 3:7 lauryl to laureth sulfate ratio imparts a nice short flow for the system. Higher amounts of lauryl sulfates may cause stringy flow whereas the higher amounts of laureth sulfate will not have optimized creaminess of the lather and may not build maximum viscosity.

Developing a Shampoo FormulaIn the past, cocamide DEA was a common alkanolamide for viscosity building and foam stability, and some formulators still use it. It is a liquid material and has balanced properties for viscosity building as well as stabilizing the foam. Higher chain amides such as oleamide DEA will generally build higher viscosities (on an equal active basis) than its coco counterpart but the foam stability will not be as good as that obtained by cocamide DEA. Some formulators use cocamide MEA to avoid the DEA. Cocamide MEA will generally build somewhat higher viscosities than cocamide DEA, but not as high as oleamide DEA. The foam stability provided by cocamide MEA is comparable to that provided by cocamide DEA. Cocamide MEA is a waxy solid and requires heat to make the finished product. Salts, such as sodium chloride, increase the viscosity of sulfate-amide systems. It is always good to run a salt viscosity curve for each formula, which can be done by adding the salt to the formula in increments of 0.2% or so. After a certain amount of salt has been added, the viscosity peaks and any more salt will actually reduce the viscosity rather than increase it. This type of curve is useful for adjusting the viscosity of the product. Some formulators purposely exceed the curve in order to reduce the stringy character of the formula. Stringy flow can also be corrected by adding a little polysorbate 20 or propylene glycol to the formula. However, these materials will reduce the viscosity as well, which is why they are added in very low quantities such as 0.1-0.5%.

Secondary SurfactantsBetaines, like cocamidopropyl betaine (CAPB), are good secondary surfactants because of their high-foaming, viscosity-building and mildness-providing properties. In some formulas, CAPB acts as sole viscosity builder. So, for example, “amide free” formulas can be made with CAPB. When used in conjunction with alkanolamides, CAPB increases the viscosity more than can be achieved with the amide alone. As a general rule, 10-20% of alkanolamide and 10-20% of active CAPB based on the active amounts of the primary surfactants is a good starting point for formulation development. For example, with 10% total actives of alkyl/alkyl ether sulfates, 1-2% of an alkanolamide and 1-2% active CAPB (or about 3-6% as supplied) is needed. Therefore a starting formula for a simple medium grade shampoo can be as follows.Ingredients%Wt.Waterq.s. to 100Sodium lauryl sulfate 10.0(as supplied 30% active)Sodium laureth-2 sulfate 26.0(as supplied 27% active)Cocamide DEA2.0Cocamidopropyl betaine6.0Preservative, perfume, dyeq.s.Citric acid (if required)to pH 6.0A wide variety of secondary surfactants improve the mildness properties of products such as shower gels, baby shampoos and baby bath products. Amphoterics, such as amphoacetates and amphopropionates, are used for mildness. Sulfosuccinates, alkyl polyglucosides, betaines, sultaines, sarcosinates, isethionates, taurates, ethoxylated sorbitan esters and amino acid-based surfactants improve mildness. An important aspect of a personal cleansing formula is a good lather profile. That is why it is important to keep some of alkyl/alkyl ether sulfate in the formula and incorporate one or a combination of some mild surfactants. Specialty ingredients include a wide range of materials such as conditioning agents, special effect additives, proteins and vitamins. Conditioning shampoos, also called 2-in-1 formulas, use conditioning agents such as fatty amines, fatty quats, polydimethyl siloxanes, organo modified siloxanes (amino functional, quaternized silicones) and quaternized polymers (cellulose and guar).Conditioning shampoos using quats and amines must be compatible with any anionic surfactants in the formula. A formulator must carefully choose the quality and quantity of fatty quat and fatty amine to avoid heavy buildup, dulling, and flattening effects in the final product. Silicones are good for shine and luster. Small amounts of silicones will do a good job of light conditioning without heavy buildup. Quaternized polymers, such as quaternized cellulose, also provide a light conditioning effect and impart static control and easy combing, if used in proper amounts.

Additives to ConsiderShampoo formulas may also include special additives. Some of these materials include: Proteins: Hydrolyzed vegetable protein, hydrolyzed wheat protein, hydrolyzed milk protein, hydrolyzed silk and hydrolyzed collagen.Vitamins: Panthenol, biotin, vitamin E acetate, vitamin A and D palmitate.Moisturizers/humectants: Glycerin, propylene glycol, sodium PCA, amino acid based surfactants and hylauronic acid.Emollients: Esters like isopropyl myristate, decyl oleate and C12-15 alkyl benzoate.Natural oils: Jojoba oil, aloe vera oil, safflower oil and almond oil. Botanicals: Chamomile, aloe vera, rosemary and hops. Aromatherapy: Lavender, ylang ylang, patchouli and other essential oils.Minor ingredients include preservatives, perfume, dye, pH adjusters and chelating agents.

Developing a Shampoo FormulaIn developing an economy shampoo formula with 6-8% surfactant solids, it is important to remember that the market is trending toward natural and biodegradable ingredients. Therefore it is important to find a surfactant system that is inexpensive yet high foaming, derived from natural, vegetable resources and biodegradable. Alkyl sulfates and alkyl ether sulfates fit the bill. You can get sodium and ammonium lauryl sulfates and sodium and ammonium laureth (or lauryl ether) sulfates that are derived from natural coconut oil. They are all biodegradable, high-foaming anionic surfactants. A good starting point for an economy shampoo includes 7% active alkyl sulfates/alkyl ether sulfate, about 1% cocamide DEA and enough sodium chloride to get the maximum viscosity. As salt is added, the viscosity starts to increase up to a certain concentration of the salt after which any more salt will reduce the viscosity. The salt / viscosity curve get affected by the quality/quantity of anionic surfactants, and quality/quantity of alkanolamides among other factors. Generally speaking, the higher the amount of anionic surfactant and amide, the lower the amount of salt it will take to reach the peak viscosity. Formulators add betaines such as cocamidopropyl betaine in shampoos for mildness, viscosity

Formulating a shampoo requires balancing the desirable properties in the formula.building and to creaminess to the lather. Cocamidopropyl betaine also affects the salt viscosity curve. Other viscosity builders such as cellulosic polymers, polyacrylates and highly ethoxylated esters will also impact the curve. So the salt curve should be run on the final formula with all other ingredients in it. So far we have talked about increasing the viscosity but occasionally, a formula gets very thick and viscous. The formula may have a long, stringy flow problem as well.

Reducing ViscosityOne way to reduce the viscosity and stringy character of the formula is to go over the peak of the salt curve and reduce viscosity by adding an excess amount of salt. This will also reduce the stringy flow property of the formula. Other techniques to reduce viscosity include adding alcohol (denatured ethyl alcohol) and /or glycols (propylene glycol). Surfactants with higher ratios of hydrophile (bulky hydrophilic group and relatively smaller hydrophobe) such as xylene sulfonates will also reduce the viscosity. Certain nonionic surfactants such as polysorbate 20 also tend to reduce the viscosity of anionic surfactant based formulas. Another important aspect of viscosity modifiers is the feel (and any other modification for example to the lather profile) of the formula, that they introduce. Temperature/viscosity and pH/viscosi-ty curves are also important selection criteria for viscosity builders. Relatively flat curves would be preferable. In other words you would want the formula viscosity to remain relatively unchanged when the temperature or pH changes during storage or use. Alkanolamides not only build the viscosity but also act as foam stabilizers. Alkanolamides also enhance “body” and provide lubricity to the formula, at relatively lower cost. Cocamide DEA will provide a relatively lower increase in viscosity but better foam stability as compared to oleamide DEA which will provide higher viscosity but less foam stability. Cellulose derivatives such as hydroxypropyl methylcellulose or hydroxyethyl cellulose provide viscosity building, foam stability and lubricity. The dispersion of these polymers may be tricky and takes time and certain kind of mixing equipment.

Polymers To TryThere are surface treated polymers available from suppliers that will be easier to disperse and hydrate in water. If there is salt and/or other electrolytes present in the formula, make sure the polymer will be able to tolerate that amount of salt.Natural polymers such as xanthan gum or guar can also be used as viscosity builders. Guar also comes as cationic active. Cationic guar will not only increase the viscosity but also add some conditioning properties to the formula. Similarly, polyquaternium-10, a cationic cellulose, adds conditioning and builds viscosity. These polymers, despite being cationic, are generally compatible with anionic surfactants. However, always run a stability test at various temperatures (room temperature, refrigerator, oven at 500°C and freeze thaw) for a new formula. Acrylates also build viscosity. Hydrophobically modified polymers that are available as 30% active liquids provide the ease of processing without all the trouble of getting a powdered polymer dispersed and fully hydrated in water. Highly ethoxylated materials such as PEG-120 methyl glucose dioleate, PEG-150 distearate, PEG-150 polyglyceryl-2 tristearate and PEG-150 pentaerythrityl tetrastearate are also used as thickeners, particularly where there are nonionic surfactants or other hard to thicken surfactants involved. Some of these thickeners, like PEG-150 distearate for example, are waxy solids that must be dissolved with heat and mixed with the batch. They also add a heavy feeling that is slightly on the sticky side. Products thickened with PEG-120 glucose dioleate may have a relatively sharp temperature/viscosity curve; i.e., there may be a sharp viscosity drop with a relatively small increase in temperature.

Test and Test AgainNo formulation work is complete without proper safety, physical, chemical, performance, stability and consumer panel testing. It is a good idea to have more than one or two final prototype formulas. Subject the formulas through these tests and then choose the final formula. But keep some formulas for back up. Another important aspect of product development is “product scale up.” Any formula, no matter how good it looks in the lab, is worthless unless it can be reproduced in your plant. The art of formulating a shampoo is the art of balancing the desirable properties in the formula and keeping the undesirables to a minimum, while achieving a specified raw material cost.In many formulas for example, an increase in viscosity can be associated with an increase in stringiness. The formulator’s job is to reach a highly desirable viscosity without the undesirable stringiness.

viernes, 20 de noviembre de 2009

HAND SANITIZERS

Hand sanitizers come in many different forms, from liquid gels to foam to, more recently, a spray. As they kill germs but don’t necessarily remove dirt and debris, sanitizers are most effective when used as a complement to regular and proper hand washing. They also work well as a substitute for hand washing when that is not an option. Proper application is key to maximizing the effectiveness of sanitizers, no matter the form. Spray sanitizers reach the greatest surface area via application in comparison to foam and gel, but all types need to then be rubbed thoroughly on all areas of hands until dry. Sprays and foam have a premeasured dose of product, while gels can also be up to the discretion of the user. The typical application size for gels is half a teaspoon.

Though the CDC recommends using a hand sanitizer with at least 60 percent alcohol content, the development of alcohol-free sanitizers has created an option that is preferable for certain market sectors, such as education, where they are being touted as safer for school children as well as inmates in correctional facilities. They are also preferable for those with sensitive skin. Alcohol-free sanitizers are available in gel, foam, and spray formats. These formulas are water-based and odorless, and tend to be less sticky on the hands, and their active ingredients offer a germ kill rate comparable to alcohol-based formulas. Alcohol-free sanitizers are also available in biobased, environmentally friendly versions.

Studies have shown that soap dispensers that are reused and opened for as-needed refills can be contaminated with bacteria — meaning that when occupants dispense soap meant to cleanse hands, they are actually contaminating those hands with illness-causing fecal bacteria. Dispensers that are sealed and refilled with cartridges that are discarded when empty help to eliminate bacterial growth on dispensers. But even sealed soap dispensers, whether they’re wall- or counter-mounted, and whether they’re touch-free or manual, need to be kept clean and free of debris, dried soap and fingerprints to ensure they look clean, continue to work properly and to prevent a cross-contamination risk.

Hand sanitizing stands have increased in popularity, due to an increased public awareness and use of sanitizers as well as the recent H1N1 flu outbreak and the role of hand hygiene in flu prevention. The proper placement of hand sanitizer stands can not only encourage building occupants to help prevent the spread of illness — it can also spread a public health message that companies and facilities want to be proactive in keeping occupants healthy. Stands, which are portable, are generally made for touch-free dispensers, which are part of the larger effort to reduce cross-contamination. They should be placed in high-traffic areas such as lobbies, cafeterias and reception areas, and at entrances and exits.

Foam soap — which is liquid in a cartridge or bottle but is dispensed as foam — is one way to encourage hand washing in facilities while at the same time saving money through reduced product usage. Each pump of foam soap uses significantly less than a pump of liquid soap, and deposits a rich lather-like foam that may promote more thorough hand washing, making it an ideal choice in higher education settings, healthcare and food service environments, where hand hygiene is critical. Foam soaps can also contain moisturizers, which gives users a more satisfying impression of the hand washing experience.

jueves, 19 de noviembre de 2009

New Silicone Polymer will drive electronic chips into the body

A group of scientists from several universities are developing thin, flexible silicon electronics on silk substrates that almost completely dissolve inside the body. The new technology offers a range of advantages. While electronics must usually be encased to protect them from the body, these electronics do not require protection. In addition, the silk substrate conforms to biological tissue before melting away over time, and the thin silicon circuits left behind do not cause irritation because they are only a few nanometers thick.

FINALLY WE WILL KNOW WHEN THE BEER IS COLD

These new types of inks, change color or dissapear when they reach certain temperatures or they are rubbed or warmed.

Activation temperature points range from low refrigeration type temperatures through normal body temperatures to high temperatures that exceed the pain threshold.

Cold Activated Thermochromic Ink is used on labels and packaging to create a color change when cooled. (Clear to Color at 15ºC / 59ºF)

Touch Activated Thermochromic Ink will vanish when rubbed or touched to reveal an image or another color printed beneath. (Color to Clear at 31ºC / 88ºF)

Touch Activated Liquid Crystal Ink will change color within the visible spectrum when rubbed or touched.Color Sequence: Black » Red » Green » Blue (25-30ºC / 77-86ºF)

High Temperature Thermochromic Ink is designed to change color just below the pain threshold alerting consumers and users to a safety hazard - Too Hot! (Color to Clear at 47ºC / 117ºF)

Hallcrest thermochromic formulations are available as a finished ink, pigment or a liquid crystal screen ink. Colors and temperatures can be customized to your application and printing capability. Thermochromic Temperature Range: -10ºC to 69ºC (14ºF to 156ºF)

miércoles, 18 de noviembre de 2009

PLASTICOS EN EL COMERCIO

En la actualidad una gran cantidad de botellas plasticas transparentes son manufacturadas con resinas de Policarbonato, PC, el cual contiene un monomero o molecula llamada Bisfenol A. Debido a las numerosas denuncias de que este ultimo es nocivo para la salud, aun cuando la FDA ( Food and Drug Administration) en estados Unidos habia decretado seguro, se ha visto ya una tendencia adelantada a cambiar de resinas para esta aplicacion. Esta quizas es la mejor oportunidad para el Polipropileno o el PET para sustituir el PC.

martes, 17 de noviembre de 2009

GREEN ALL PURPOSE SOLVENTS

As safe as Di-Propylene Glycol Monomethyl Ether, ( Glycol Ether DPM), may be to the environment, the most recognized easily biodegradable solventes for multiple uses are more natural derived.

Vertec BioSolvents Inc. is a unique technology, manufacturing and marketing company dedicated to providing bio-based, renewable resource alternatives to petroleum-based solvents, a business dedicated to “Green” chemistry solutions to industry problems. The company manufactures and sells biosolvents and blends based primarily on four major ingredients – ethyl lactate, fatty acid methyl esters (soy methyl esters), d-limonene and ethanol for a variety of specialty applications in industrial and agricultural markets. The company has intellectual property for these blends and applications. Vertec’s solvents are now being used in many specialty product formulations and applications, such as: inks, agricultural products, specialty coatings, paints and coatings line flush and plastics recycling.

jueves, 12 de noviembre de 2009

NEW iPHONE CAN DETECT CHEMICALS IN THE AIR

Jing Li, a physical scientist at NASA's Ames Research Center, along with other researchers developed a proof of concept of new technology that would bring compact, low-cost, low-power, high-speed nanosensor-based chemical sensing capabilities to cell phones. The device is about the size of a postage stamp and is designed to be plugged in to an iPhone to collect, process and transmit sensor data. The new device is able to detect and identify low concentrations of airborne ammonia, chlorine gas and methane. The device senses chemicals in the air using a "sample jet" and a multiple-channel silicon-based sensing chip, which consists of 16 nanosensors, and sends detection data to another phone or a computer via telephone, communication network or Wi-Fi.

Bio Degradability of PP

The biodegradability of PP can be accelerated by modifying the level of crystallinity or by incorporation of carbonyl groups by adding pro-oxidants to masterbatches or through exposure to UV irradiation. In this paper we show how to improve the biodegradation of PP by adding cobalt, calcium or magnesium stearate to Ecoflex, PP or Ecoflex/PP blends. The effect of the pro-oxidants on biodegradability was assessed by examining the mechanical properties and fluidity of the polymers.

NEW METHACRYLATE RESIN

Esstech announces FIT 852™ Resin, a methacrylated monomer that shrinks 2% on cure.

It is a chronic problem across industries that resins, monomers or composites contract during polymerization. Standard industry resins can reduce volume by 5% upon curing. Common urethanes lose 4% of volume when polymerized.

Resin shrinkage leads to increased internal stress, debonding, fracture, leakage and ultimately premature failure of your cured system. The reduced shrinkage and enhanced toughness of FIT 852™ Resin is quickly becoming the new standard in curable systems!

To obtain literature and samples, email techsupport@esstechinc.com, or call Esstech at 610-521-3800.

miércoles, 11 de noviembre de 2009

NEW PANEL OIL SEPARATOR

Revolutionary Oil Water SeparatorsHydro Quip, Incorporated

Hydro Quip, Inc. manufactures a complete line of revolutionary high-efficiency above and below ground oil water separators that achieve superior results. Our separators will remove 99.99% of free and dispersed non-emulsified oil droplets 20 micron in size or greater to produce an effluent quality of 5 ppm or better.

Good separation or collection is now also achievable with the oil skinner, that is a cable that continuosly collects oil from water and deposits it into an attached container.

CHEMICAL LIBRARY AND FORMULARY

Over 80,000 professionals worldwide rely on Chemidex as the most comprehensive, global resource for chemical industry professionals. Members have access to material data sheets including MSDS, TDS, brochures, technical articles, white papers, and starting-point formulations from leading suppliers. Register today for a complimentary membership

NEW CONCRETE POLYMER

If concrete is the most prevalent building material on the planet, why develop a different type? Studies show that producing the Portland cement necessary to make concrete generates five to eight percent of the world's CO2 emissions. So, researchers at Louisiana Tech University are developing a geopolymer concrete (GPC) that requires no OPC (ordinary Portland cement) and uses a waste product from coal fired power plants — fly ash — as its filler. GPC is more resistant to corrosion than OPC, and resists fire as hot as 2,400 F. Over its life cycle, GPC is expected to reduce greenhouse gas emissions as much as 90% compared with OPC.

domingo, 20 de septiembre de 2009

BEST USE OF CELLULOSE ESTER AS THICKENERS

When using Carboxy methyl-ethyl-propyl cellulose or other cellulose ester to obtain a high viscosity solution, the best way to obtain a quick dissolution in water, even cold, with no lumps, is to lower the pH of the water to 7 or 6 , add the powder and after its all suspended and distributed, the raise the pH to 8- 9 or more, this will complete the thickening process smoothly

martes, 1 de septiembre de 2009

HOW TO CONVERT IRON OXIDE (RUST)

The most convenient way to convert iron oxide , rust, is to use a formula based on tannic acid, round 5-9 % and use a polymer to form a bond to the surface. On application, the rust will start converting to the tannate salt and change to a black color. This will remain so for long, protecting the metal surface without having to paint it.

miércoles, 29 de julio de 2009

CHEMICAL NEWS

Sipchem and Hanwha Join Forces in New Petrochemical ProjectSaudi International Petrochemical Company (Sipchem) and South Korea’s Hanwha Chemical recently reported their joint investment of $90m (€64.8m) in a new petrochemical project. Under the agreement, Hanwha will receive a 40% share of the [ethylene vinyl acetate] (EVA) product sales, with the 60% remaining marked for Sipchem. Located in Al-Jubail, Saudi Arabia, the project includes a 200,000 tonne/year EVA plant and a 125,000 tonne/year plant for polyvinyl products. Ownership of the plants will be divided with 75% belonging to Sipchem and 25% going to Hanwha. The products produced will be used in a variety of applications including hot melt adhesives, hot glue sticks and many others. Additional U.S. Plants to Close at Dow ChemicalThe board of industry giant Dow Chemical has approved a restructuring plan to close more U.S. plants. Those ethylene -derivative plants affected are located in the Louisiana towns of Hahnville and Plaquemine. These recent closures are in addition to numerous other similar shutdowns recently implemented as part of the Company’s restructuring program that was announced in the fourth quarter of 2008. The restructuring program was in line with the Dow’s goal of achieving $1.3 billion synergies on the acquisition of Rohm and Haas. Included in the plan was a charge for the elimination of 2,500 positionsCelanese to Close French Subsidiar Celanese Corporation has reached a final agreement with workers on how the chemical maker will shut down its Acetex Chimie subsidiary, located in Pardies, France. As a result of the closing, all 350 plant employees will lose their jobs. All operations at the site are expected to cease by December. The facility produces two chemicals, including acetic acid. The 350 employees losing their positions are at management, maintenance, operations and support levels. Celanese evaluated the facility earlier in the year, focusing on factors such as competitiveness in their respective markets, customer demand, raw material costs, and labor costs. As a result of the findings, the Company determined that the site should be closed. Production of the same products will continue at existing facilities in Texas, China and Singapore. DuPont Titanium Technologies Raises Prices for Its Ti-Pure® Titanium Dioxide Products Abroad DuPont Titanium Technologies (DTT) recently announced it will increase the price in the U.S. dollar markets of Africa, Eastern Europe, and Middle East regions for all its Ti-Pure® titanium dioxide (TiO2) grades. Prices in those regions will increase by $150 per tonne (USD). This increase is effective Aug. 1, 2009 or as permitted by contract and is in addition to an earlier increase in the same markets which was announced on May 15, 2009

sábado, 18 de abril de 2009

INITIATIVES TO HELP DECIDE WHAT SAFER PRODUCT TO BUY

SC Johnson Starts Listing Product Ingredients Publicly

By GreenBiz Staff, GreenBizPublished March 13, 2009

RACINE, Wis. -- SC Johnson has started listing all of the ingredients in products on a new website, and is also making the ingredient lists public on product labels and through a consumer hotline. The ingredient website, http://www.whatsinsidescjohnson.com/, launched this week and so far includes ingredient lists for Nature's Source cleaners, Windex outdoor spray, Shout wipes and Glade candles and sprays. The company will continue to add products over the next three years, aiming to have all ingredients for air care and home cleaning products public by January 2012.SC Johnson is listing not only the product ingredients, but providing explanations of what the ingredients do. The company is also taking ingredient listing a step further than other companies by pledging to list details of preservatives, dyes and fragrances. Although, in order to protect proprietary details, SC Johnson will list all ingredients that could potentially be in fragrances.The company's ingredient listing is an outgrowth of a voluntary industry initiative to list ingredients online, on product labels, via toll-free numbers or other non-electronic means.It also comes just weeks after public interest law firm Earthjustice filed a lawsuit against cleaning product makers Procter & Gamble, Colgate-Palmolive, Church & Dwight Co. and Reckitt Benckiser Group for not complying with a New York law that requires companies selling cleaning products in the state to file reports listing the chemicals in products.Earthjustice says it did not include SC Johnson in that lawsuit because when Earthjustice informed SC Johnson it was not following the law, the company began speaking with Earthjustice and other groups about what it could do to come into compliance.SC Johnson's ingredient website will provide listings in both English and Spanish, with the Spanish listing to be added later this year. SC Johnson Canada will start listing ingredients next year in English and French.SC Johnson is also working to phase phthalates out of its products, an initiative it started last summer, when it began talks with suppliers on how to remove the phthalate DEP from fragrances. Some new and reformulated products are already being produced without phthalates.

EPA AND ANIMAL TESTINGS

EPA Moving Away from Animal Testing to Assess Chemical Toxicity Risk

By GreenBiz Staff, GreenBizPublished March 25, 2009

WASHINGTON, D.C. -- The U.S. Environmental Protection Agency is reducing its reliance on animal testing to assess human risk of chemical toxicity and will instead focus more heavily on the tools made possible by advances in molecular biology, genomics and computational modeling.The move is part of the EPA's effort to find better, cheaper and faster ways to screen thousands of chemicals for human risk, including the ways in which toxicity occurs, the impact of long-term exposure to various chemicals, and how chemicals effect genetic variations of the population. "Right now, there isn't enough capacity to test all the chemicals we want information on," Robert Kavlock, director of EPA's computational toxicology program, told GreenBiz.com Wednesday.The agency asked its various departments about high-priority chemicals for which they'd most want information. After compiling the list of nearly 10,000 chemicals and consulting the public literature, the EPA discovered it didn't know whether two-thirds of the chemicals on this list caused cancer in animals; for 90 percent of the chemicals, it didn't know their effects on reproduction. The "U.S. Environmental Protection Agency's Strategic Plan for Evaluating the Toxicity of Chemicals," (PDF) released today, will also enable the agency to study how toxicity impacts children. It expects the new approach will yield significant savings. For example, companies may have to pay upwards of a half-million dollars to perform an endocrine disruption screening on individual chemicals, as may be required by the end of the year for chemicals that include food use pesticides, but the new approach may trim the cost to about $20,000."For people who are developing green chemistry, this may allow them to look for an alternative chemical and profile that chemical for $20,000," Kavlock said, adding the new approach may serve as a way to validate whether one chemical is greener than another.The strategic plan builds upon the findings of a 2007 report from the National Research Council which advocates transforming the way human toxicity risk is determined by focusing on identifying and evaluating toxicity pathways.The EPA will still use animal testing for the foreseeable future, but in smarter ways, Kavlock said. "For a long time there will be a need for animal testing," he said. "They've served their purpose well. The only way we can study some things is in animals." Kavlock expects the testing strategy to be fully deployed within 10 years but believes useful applications will be released within two years.

jueves, 9 de abril de 2009

EPA and Green Disinfectants

EPA to Allow Green Claims for Disinfectants & Sanitizers

According to ISSA, U.S. Environmental Protection Agency (EPA) officials have stated they will recommend the adoption of a policy that allows suppliers to make valid claims of environmental preferability in relation to the marketing of disinfectants and sanitizers. This statement represents a significant departure from the agency’s well-entrenched policy that prohibits “green” claims to be made in conjunction with the promotion of any EPA-registered product, including antimicrobial pesticides.

Specifically, EPA officials are expected to recommend that the agency allow suppliers to make factual claims of environmental preferability in conjunction with disinfectants and sanitizers, according to Marty Monell of the EPA's Office of Pesticide Programs. In addition, Ms. Monell stated that she will also recommend that a policy be established that would allow the use of ecolabels in conjunction with the marketing of hard-surface antimicrobial products. In this regard, it is expected that the latter policy would be conducted in cooperation with the EPA Design for the Environment Formulator Program (DfE).

“I am very pleased to see this development from EPA that will make it easier for green consumers and manufacturers to clearly identify greener disinfectants, which in turn will help eliminate confusion in the marketplace and accelerate green cleaning in critical segments such as health care, schools, and others with vulnerable populations,” said Stephen Ashkin, president, The Ashkin Group.

While the process is not yet complete, EPA will make the recommendations on green claims at the April 22-23 meeting of EPA’s Pesticide Policy Dialogue Committee. The green-claim policy recommendations are based on the work product of the EPA Working Group on Comparative Claims upon which sit Ashkin and Bill Balek, director of legislative affairs, ISSA.

“This latest development by EPA is another indication of the growing maturity of green cleaning, and the increasing availability of environmentally preferable products that also meet the most stringent performance, and health and safety requirements,” said Balek.

In the meantime, EPA and DfE will continue to conduct the internal pilot which is designed to identify the parameters under which the DfE ecolabel could be conferred upon certain disinfectants and sanitizers. Once the internal pilot is completed, it is expected that EPA will conduct an external pilot that presumably would open the process up to manufacturers and distributors.

viernes, 27 de febrero de 2009

NEWS ON "GREEN" PACKAGING

February 27, 2009 Edited by Rick Lingle

Pearson Acquires Goodman Packaging Equipment >>

Pearson Packaging Systems, a leading manufacturer of secondary packaging equipment announced December 3, 2008, it has signed an agreement finalizing the acquisition of Goodman Packaging Equipment, a Chicago-area based producer of top loading case packers. Click here to read more.

Pearson Packaging Systems

Pearson's New GTL-UNI Case Packer (Goodman Universal™) >>

The Pearson GTL-UNI Case Packer (Goodman Universal™) is a fully automatic case packer for horizontal packing, custom built to your project specifications. Click here to learn more on top loading from Pearson

Pearson Packaging Systems

Order Parts Online, Save 10%! >>

Order parts today on Pearson's website and save 10% with the promo code "Buy Online"! Click here to order today!

Pearson Packaging Systems

Pearson's New VP15-T VersaPack Hand Pack System >>

Pearson's new VP15 VersaPack® Hand Pack System is the perfect solution for all of your hand packing operations. Click here to learn more on automating your manual operations!

Pearson Packaging Systems

Thanks for Attending the Robotic Invasion! >>

You survived the Invasion! But the adventure continues! Call 800.732.7766 today to see how you and Pearson can solve your Secondary Packaging Machinery Needs!

Pearson Packaging Systems

FEATURED ARTICLE

Optimizing the packaging-sustainability alliance

The trend of sustainability executives provides packaging professionals with opportunities for increased visibility, reliance, and clout.

By Sterling Anthony

IN OTHER NEWS

SpoonLidz offers a value-added solution >>

Greener in Europe: Cadbury's 'eco-eggs' >>

It's official—recession is top of mind >>

Sustainability executives: They have multisyllabic, imposing titles, that ascend all the way to vice president. Their growing numbers reflect the recognition that sustainability is a source of competitive advantage. Their job descriptions charge them with devising and implementing environmental strategies that are not merely compliance-driven but proactive and innovative. Toward that pursuit, some of the strongest allies available to the sustainability executive are packaging professionals.

But packaging professionals should not assume that their pivotal role is adequately understood by the sustainability executive; rather, they should take the initiative in forging an alliance that furthers the company's mission, goals, and objectives.

Sell the basics

Sustainability encompasses everything that the company does that impacts air, soil, water, and people; therefore, the concerns of the sustainability executive extend far beyond packaging. Still, packaging is unique, a truth that should be sold to the executive, to provide her with the perspective necessary to derive optimal value from the function.

Throughout society, packaging is ubiquitous and conspicuous, ever-visible to stakeholders, such as investors, consumers, retailers, regulators, and activists. Those stakeholders often conveniently—though not always justifiably—regard the physical packaging as an index of the company's commitment to sustainability because other company initiatives are less obvious. Whether that perception of packaging is to be applauded or bemoaned is not the issue; rather, the company should accept it as reality, in order to use packaging for strategic purposes. It's that reality that should assure packaging a high priority within the sustainability executive's plans; otherwise, the company's sustainability efforts won't have a credible "public face".

Additionally, in packaging, the sustainability executive has a communication medium that's cost-effective and far-reaching, and that can be used to convey environmental claims not directly tied to packaging. Such includes the sourcing and disposal aspects of ingredients and components; awards; memberships and sponsorships; certifications—the list goes on

Agree on philosophy

The sustainability executive's duties cut across all the company's sourcing, production, and distribution activities; hence, they are interdisciplinary and require a systems approach with its inherent trade-offs. To varying degrees, the same can be said of the duties of the packaging professional, enabling him or her to demonstrate to the sustainability professional that scope of the job and the philosophy required for success are understood.

The kindred ties can be further strengthened through a shared philosophy that sustainability is fraught with uncertainties, complexities, and contradictions. For example, there are uncertainties as to probable regulations; complexities owing to a multiplicity of SKUs; and contradictions when a drive for lower package-to-contents ratios collides with consumer demands for single-serve and portable packages. By background and experience, the packaging professional should be able to establish rapport with the sustainability executive, assuring her that he's a strong team member.

After all, decades before sustainability entered the corporate dictionary, packaging professionals were responding to environmental mandates.

And at least equally far back, packaging professionals were light-weighting, palletizing for improved cube utilization, etc. —though the reasons had more to do with cost savings ...

miércoles, 18 de febrero de 2009

BEST PAINTS AND COATINGS FOR METAL AND CONCRETE TANKS

Go to the link www.polyurea.com and see the advantages of formulating with these polymers to obtain a very fast cure coating, with excellent adhesion and great resistance, flexibility and durability.

EPA GETS INVOLVED IN GREEN MOVE

To have a good look at what the EPA is reccomending(more inclined to endorse its use)regarding raw materials for cleaners and commodities formulations, go to www.cleangredients.com

jueves, 5 de febrero de 2009

NANOCHEMICAL TECHNOLOGY

THE LEGAL SIDE

Small particles may present big regulatory issues

Published in Packaging World Magazine, July 2008 , p. 24

Written by Eric F. Greenberg, Attorney-at-Law

Today we take up small matters.

Not small matters in the sense that they will have small consequences, but small in the old-fashioned sense.

The subject today is “engineered nanoscale materials.” An emerging science, “nanotechnology” has already proven to have promising applications for a whole range of technologies, including drugs, food ingredients, and food packaging. But there are questions about whether the existing legal framework is sufficient to address the special challenges presented by ENMs.

An ENM is one with a particle size of 100 nanometers or smaller. A nanometer is one billionth of a meter. That’s about 1⁄100,000 of the width of human hair.

Such particles are already in use in a range of consumer products, including paints, coatings, clothing, drugs, cosmetics, foods, and, most relevantly here, food packaging.

When you intentionally make particles so very small, they often can have different characteristics and perform differently than the traditional-sized particle of the chemical. The nanoparticle has a lot more surface area than the larger particle, and it can be stronger or more effective at various chemical and physical properties. Carbon nanostructures and metal oxides have already been manipulated for beneficial properties at nanoscale.

Various regulatory agencies and other institutions have begun to examine a range of important regulatory issues raised by ENMs. One that has examined the regulatory challenges presented by these materials has been the Project on Emerging Nanotechnologies within the Washington, D.C.-based Woodrow Wilson International Center for Scholars, in collaboration with the Grocery Manufacturers Assn., an industry trade group. The participants included government representatives from the Food and Drug Administration, the U.S. Department of Agriculture, and the Environmental Protection Agency; representatives of industry (I was one of them); various trade organization representatives; and consumer advocacy organizations.

Called the Case Study Project, the effort was spearheaded by Michael R. Taylor, a former FDA and USDA official who is now a research professor at George Washington University School of Public Health and Health Services.

The Case Study Project’s report was issued this spring. It was authored by Mr. Taylor and was based on the work of three working groups: one on law, policy, and process; one on science; and one on industry stewardship.

The primary focus of the group’s discussions was the adequacy of existing regulatory frameworks to properly address the new and different safety challenges raised by ENMs, with respect to human and animal health, as well as environmental exposure, in the context of food packaging.

The project undertook an examination of food packaging as one of its first orders of business. This was certainly logical, since the use of nanotechnology is already being explored in packaging. The project created three imaginary “case studies” in which particular product types were imagined, and questions were discussed about whether these products could be properly evaluated under the existing regulatory regime for food contact notifications, food additive petitions, GRAS substances, and related principles.

The report concluded that the most challenging issues relate to the application of scientific and technical criteria for evaluating the food safety aspects of ENMs in food packaging, in light of their novel properties.

It has been recognized that nanomaterials are sometimes capable of entering and interacting with the body in ways that differ from their traditional forms. However, it was not possible yet to generalize about when such materials will exhibit certain characteristics, and when they won’t.

The report also indicated, “The applicable laws are by design stringent in imposing on sponsors the burden of proof on the safety of food contact substances, and FDA and EPA implement these laws in keeping with sound safety assessment principles that impose significant data collection requirements on sponsors. This approach provides a high level of consumer protection, but, given the current state of scientific knowledge and need for case-by-case evaluation, it also will require scientific investment and innovation in order to satisfy established regulatory standards.”

The report generally concludes that the regulatory framework is strict and sufficient to address the special challenges of ENMs. One of its primary conclusions, though, was that ENMs would have to be evaluated on a case-by-case basis to determine whether any individual project presented new and different safety issues and if so, how they might be sufficiently evaluated.

The report advises those who are developing ENMs for use in food contact substances to engage in early consultation with FDA to assure that their particular material will be adequately addressed by existing safety requirements. The report recognizes that FDA might decide that a food contact material incorporating a nanoscale material presents unique safety questions that require a full Food Additive Petition and its related notice-and-comment rulemaking procedures, rather than the usually quicker Food Contact Notification process. But the existing law already allows FDA to do that when FDA determines that a petition, rather than an FCN, is “necessary to provide adequate assurance of safety.”

Moreover, because the science of nanotechnology is still emerging in a variety of technological contexts, the likelihood of reaching a conclusion that a given ENM is “Generally Recognized As Safe” is small, at least for most materials and for the near future.

At the end of the day, nanotechnology is still new, and its novelty virtually guarantees that all packagers will hear more about it—in this space and elsewhere—in the coming years as regulators at FDA and other agencies continue to grapple with the issue of whether they think the safety of these revolutionary products is sufficiently assured by current provisions.

Eric can be reached at greenberg@efg-law.comThis email address is being protected from spam bots, you need Javascript enabled to view it ,

and visit his firm’s Web site at www.ericfgreenbergpc.com.

Now, November 2009, the EPA has decided to invest a considerable amount of money and time in a research that will be conducted in their own labs to help determine if NANOMATERIALS are really safe to use. More information at: www.epa.gov/nanoscience

miércoles, 14 de enero de 2009

WONDERS OF CHEMISTRY

GO TO THE LINK BELOW TO FIND THE SURPRISING CHEMICAL FORMULAS THAT ARE BEHIND OUR EVERYDAY LIFE PRODUCTS AND ITEMS

http://pubs.acs.org/cen/whatstuff/stuff.html

IT IS A MARVELOUS AND EXCITING SCIENCE !!!

lunes, 12 de enero de 2009

SAFE FUNGICIDE FOR PAINTED WALLS

Taken from two publications from the “Paint and Coating Industry” Magazine (www.pcimag.com) from 07/08 edition, pages 54 and 60, we can see that the active ingredient Carbamate, like IPBC (3-Iodo-2-propynyl butylcarbamate),is being considered safe and green, for the control of fungi and bacteria on painted wall surfaces. Also there is a paragraph that lines some of the drawbacks of the Silver Ion technology.

viernes, 9 de enero de 2009

Vistas de página en total

GREEN CHEMICALS

Also the materials have to meet with toxicity and health requirements regarding inhalation, dermal and eye contact. There is also a specific list of materials that are prohibited or restricted from formulations, like ozone-depleting compounds and alkylphenol ethoxylates amongst others. Please go to http://www.greenseal.com/ for complete information on their requirements.

For information on current issues regarding green chemicals, see the blog from the Journalist Doris De Guzman, in the ICIS at: http://www.icis.com/blogs/green-chemicals/.

Certification is an important — and confusing — aspect of green cleaning. Third-party certification is available for products that meet standards set by Green Seal, EcoLogo, Energy Star, the Carpet & Rug Institute and others.

Manufacturers can also hire independent labs to determine whether a product is environmentally preferable and then place the manufacturer’s own eco-logo on the product; this is called self-certification. Finally, some manufacturers label a product with words like “sustainable,” “green,” or “earth friendly” without any third-party verification.

“The fact that there is not a single authoritative standard to go by adds to the confusion,” says Steven L. Mack M.Ed., director of buildings and grounds service for Ohio University, Athens, Ohio.

In www.happi.com of June 2008 edition, there is a report of Natural formulating markets that also emphasises the fact that registration of "green formulas" is very confused at present, due to lack of direction and unification of criteria and that some governmental instittion (in my opinion the EPA) should take part in this very important issue.