With so much attention paid to

cleaning and disinfecting surfaces and items like linens, infection

control-minded facilities often over- look the source of more than one-third of

nosocomial infections — the air. Long-established airborne precautions are rarely

used in long-term care facilities, according to the Agency for Healthcare

Research and Quality. Experts advise how to reverse that.

1.Understand the risks. Influenza

is by far the most prevalent airborne pathogen, and tuberculosis is the second

most serious, according to Gina Pugliese, RN, MS, FSHEA, vice president

emeritus of the Premier Safety Institute®. That's because the elderly are at

high risk of reactivation of an old, latent infection, and early symptoms are

not the usual cough and high fever.

Other common airborne infections

include Norovirus, C. diff, MRSA, pneumonia, respiratory syncytial virus (RSV),

parainfluenza, coronavirus, rhinoviruses, adenoviruses, disseminated shingles

and human metapneumovirus.

Another surprise: Many of these

also can spread in other ways.

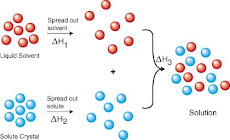

“Illnesses transmitted through

the air occur when infectious agents spread via the airborne or droplet routes.

But contact with these germs can also spread these illnesses,” notes Deva Rea,

clinical science liaison for PDI.

2. Know your facility's

vulnerabilities. Airborne germs are opportunistic and seek weakness in places

like heating, venting, air-conditioning and water systems.

“Legionella pneumophila does

a great job of surviving in water and in ‘biofilms,' which can develop in water

pipes and other man-made devices,” notes Deb Patterson Burdsall, Ph.D., RN-BC,

CIC, FAPIC, an infection preventionist who also serves as faculty and author on

various projects related to long-term care for the Association for

Professionals in Infection Control and Epidemiology.

Ironically, the air itself is “a

central yet often overlooked transmission vector for dangerous pathogens,” says

Olivia Easly, marketing manager for Novaerus. And while airborne illnesses

typically find a path through coughing and sneezing, germs easily can be

aerosolized through such activities as bed making and vacuuming, she says.

Another vulnerability: group

activities. “These activities may increase communicable infectious disease

exposure and transmission,” Rea says. “The same is also true for occupational

and physical therapy activities.”

3. Housekeeping and maintenance

are vital to prevention. “Environmental service personnel are essential to

infection prevention. Regardless of the pathogen, good environmental cleaning

and disinfection are main prevention strategies,” Rea notes.

Facility maintenance workers are

critical when dealing with certain airborne illnesses such as TB by providing

monitoring of airborne isolation rooms under negative pressure, she adds.

Housekeepers should under- stand

that shaking soiled linens can aerosolize germs, advises Bill Brooks, North

American sales manager for UniMac®.

4. Preparing a rapid response to

an emerging infection is critical. Pugliese notes that staff vigilance can

prevent widespread infection. That's why it's important to understand the

sometimes puzzling early symptoms of an illness such as TB. Once detected, “the

usual principles of airborne isolation apply, which require negative pressure

ventilation and t-tested respirators, per OSHA,” she adds.

“If an outbreak of any airborne-

related illness occurs, it may be necessary to restrict admissions, visitors,

and cohort residents with the same illness,” Rea says.

5. Know how to protect your most

vulnerable residents. Immunocompromised residents can skew normal isolation

precautions.

"With some viral illnesses

such as influenza, RSV, norovirus and adenovirus, an immunocompromised patient

may shed the virus for longer periods of time,” observes Rea. “So it's

recommended to keep patients on isolation precautions for an extended

duration.”

6. It bears repeating: Caregivers

are often unwitting carriers and transmitters of airborne illnesses. That's why

training and adequate and plentiful personal protective equipment are

essential.

Basic, sound personal hygiene

practices such as regular hand washing and staying home when sick should be

enforced. It's also not too late to receive a u shot.

As noted, coughed or sneezed

aerosolized droplets aren't the only way pathogens reach the lungs. Germs on

contaminated surfaces and hands have an insidious way of reaching the mouths

and noses of patients. As Easly reminds, “the CDC and WHO have declared hand

disinfection as the most important standard measurement of hand hygiene in

healthcare facilities as it can lead — if correctly performed — to a drastic

reduction of nosocomial infections.”

Mistakes to avoid

1. Relying on consumer-grade air

filtration. The germ- laden air of nursing homes calls for industrial strength solutions.

Consider air sterilization systems that eradicate, not filter, germs.

2. Overlooking vulnerable areas

and practices. Biofilm in standing water is a breeding ground for illnesses.

Shaking soiled linens can actually aerosolize numerous pathogens.

3. Neglecting to have air

isolation precautions, including negative pressure rooms, available when a

nasty airborne infection is first spotted.