What are Wax Emulsions?

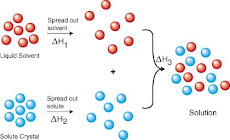

Wax emulsions and dispersions are formulated additives made of fine and stabilized wax particles, homogeneously distributed in water. Being in the liquid form, they are easily incorporated into coatings and inks formulations by simple mixing.

Wax emulsions and dispersions are formulated additives made of fine and stabilized wax particles, homogeneously distributed in water. Being in the liquid form, they are easily incorporated into coatings and inks formulations by simple mixing.- Wax emulsions normally have particle size < 1µm, and therefore, a minimized effect on the coating gloss

- Wax dispersions (either water or solvent-based), have a particle size typically > 1-2µm

Their very fine particle size ensures thorough, homogeneous incorporation with other ingredients of the formulation, maximizing the required effects.

Wax emulsions can be stabilized by either non-ionic emulsifiers (steric mechanism) or by ionic emulsifiers, most often anionic (electrostatic mechanism). Combining anionic and non-ionic emulsifiers provides the emulsion the optimum stability because wax particles are protected through both stabilization mechanisms.

In addition, each stabilization mechanism not only has its own advantages and limitations but also significantly impacts the overall formulation giving added flexibility in formulating.

Continue reading or click to go on specific section of the page:

- What factors you should consider while formulating with wax emulsions?

- How wax emulsions work?

- Learn About Benefits of Wax Emulsions in Detail

- Popular Application Areas of Wax Emulsions

Factors to be Considered While Formulating Wax Emulsions

Wax emulsions are now well established and extensively used in various aqueous formulations. These ready-to-use wax emulsions can be easily incorporated into a formula by simple mixing.

The wax properties that have the greatest impact on formulation performances include:

- The Melting Point: When curing is required, it is important that the wax has a lower melting point than the curing temperature. Thus, the wax can:

- The Coating Thickness Layer: In order to maximize the wax effects, it is important to have the highest dried wax density to be at dried film surface.Hence, the wax emulsion should have a particle size as closest as possible to the thickness of the coating layer

Sometimes a wax emulsion with a smaller particle size performs equally well, provided that the concentration is correctly adapted. - pH of the Wax Emulsion should be within approximately one unit of the system to which it is added. If necessary, the pH of the emulsion can usually be adjusted using aqueous ammonia or acetic acid.

- The Type of surfactant can also influence compatibility with the other components, as well as the overall formulation stability. Matching the emulsion charge with the coating charge enhances stability.

- The Order of Component Addition: In water-based formulations, the order of component addition can be a critical factor in maintaining stability. Agglomeration can be prevented and overall stability maximized by adding the wax emulsion last. A further dilution of the emulsion with soft or demineralized water before incorporation can also reduce the shock.

- The Regulatory Aspects of Waxes: If the emulsion is intended for food contact use (in a coating or in a package), both the wax and other incorporated additives (emulsifiers, antifoams, biocides etc.) must be in compliance with applicable statutes and regulations (FDA, BfR, European Directives, Kosher Certification etc.).

- Determination of Wax content in a Formulation

Mechanism of Action of Wax Emulsions

The Blooming Mechanism

Molten wax particles float (or bloom) to the surface. The coating cools and re-crystallization of wax particles takes place, forming a thin but continuous wax-enriched surface layer.

- The softer the wax or lower the melting point, the more predominant the blooming mechanism becomes

- The compatibility between the wax emulsion and other formulation components determines the wax migration rate

The Ball Bearing Mechanism

In this case, solid wax particles migrate individually or protrude through to the surface.

By protruding slightly above the coating surface like ping-pong balls floating on a pool of water, they:

- Act as a physical spacer, and

- Prevent another surface from coming into close contact

Hard and high melting point waxes (HDPE, PTFE) operate using this mechanism under certain conditions. Both the particle density and the extent of protrusion influence the magnitude of the effect.

Once at the surface, the layer of wax particles has the ability to modify the Coefficient of Friction (CoF) of the substrate, imparting the desired characteristics. This explains why waxes are often classified as "Surface Conditioner Additives".

Benefits of Wax Emulsions

Waxes are typical additives that significantly influence the surface properties of any coatings by modifying the surface free energy. This has an impact on properties such as:

- Anti-blocking

- Slip & Mobility

- Abrasion Resistance

- Water Repellency

- Touch & Feel

- Matting Agent

- Black Heel marks

All of them are critical properties in the paint, coating and ink applications. Hence, waxes are often classified as Surface Conditioner or Modifier Additives.

Wax Emulsions as Anti-block Agents

Anti-blocking is a term defining a non-stick condition between two surfaces or the resistance to adhesion between two surfaces under the influence of:

- Temperature

- Relative humidity, or

- Pressure

A very well-known example of a blocking condition is when a freshly painted window frame is closed too soon. Sometimes, it can be very difficult to open the window again. Factors affecting blocking include:

- Coating surface-free energy

- Topography of the coatings

- Hardness, and

- Tg of the polymer

Wax emulsions as anti-blocking agents are also used extensively for items that are coated, dried and immediately stacked, rolled up for storage or shipment.

Effect of Wax on Slip & Mobility

Slip properties (or lubricity) represent the ability of two surfaces to glide over each other without causing any mechanical damage. Good slip properties require that the slip additive concentrate to the surface during and immediately after application and curing.

This is explained by the fact that wax crystals in the solid state are the main factor responsible for the characteristic of slip.

- Inks, OPV's & Primers,

- Paper, Film, & Foil Coatings

- Metal coatings

Slip resistance is the ability to manipulate the surface energy by increasing the coefficient of friction of a cured coating. This can be realized by addition of wax surface modifiers.

In particular, polypropylene waxes or wax emulsions:

- Control slip without adversely affecting scratch and mar resistance

- Have good migration performance which results in an increased wax density on the coating surface

When formulating with polypropylene wax emulsions, it is crucial to adapt the particle size of the emulsion to the coating layer, in order to maximize the wax effects on the coating surface.

Wax emulsions are used for their slip resistance property in Floor Polish.

» Check Out Various Wax Grades used as Slip Control Agents!

Effect of Wax on Abrasion Resistance

Abrasion resistance is produced by a combination of basic characteristics such as elasticity, hardness, strength, toughness, and in some cases, thickness.

It has also been established that a trend similar to that of slip additives exists between the wax hardness and the capability of the wax to resist rubbing damage.

Thanks to its mar, scratch and rub resistance properties, wax emulsions are used in a wide range of applications such as:

- Architectural Coatings & Floor Polishes

- Paper Film, & Foil Coatings

- Inks, OPV's & Primers

- Metal Coatings

» View Commercially Available Waxes for Scrub & Mar Resistance

Wax Emulsions for Water Resistance

Water repellency or water resistance is another important property obtained or improved with waxes. As the name implies, this characteristic is the protection of a surface against water penetration (in liquid form).

Depending on formulation, the protection may be temporary or very durable and long-lasting.

Thanks to this property, wax emulsion is a key ingredient in a wide range of formulation for:

- Wood Coatings

- Architectural Coatings & Floor Polishes

Effect of Wax on Touch & Feel

Although coatings are usually applied to provide optical effects (color, gloss or matting etc.) or to protect a substrate, some applications also require the surface to have tactile properties.

- In modern car interiors, coatings with a soft-feeling are applied on plastic substrates (mainly PVC) such as instrument panels and door handles to convey a "leather-like touch", i.e. a feeling of smoothness and luxury.

- With electronic devices (PCs, mobile phones, etc.) a "soft-feeling" effect created by specialized coatings is becoming increasingly more in demand.

By employing a coating that incorporates coarse wax particles, a rough and uneven surface is created at the microscopic level that is very similar to that observed with matting agents. Because tactile properties are largely dependent on the coating formulation, it is important that the wax particles protrude through the coating layer and this requires a particle size larger than the film thickness.

Thanks to this texturizing effect, wax emulsions are commonly used in Wood and Plastic Coatings.

Matt Effect Using Wax Emulsions

Providing wax dispersions have a particle size much higher than 1 µm, they will significantly reduce the gloss, by introducing micro-roughness on the coating surface. The so-created uneven surface will cause the light to be scattered.

The degree of the micro-roughness is determined by the number of particles present at the surface, which directly depends on wax properties such as:

- Particle size and particle size distribution

- Particle density

- Amount of matting agent incorporated

Thanks to this matting property, wax emulsions are widely used in wide range of applications such as: Architectural, Wood coatings and Inks, OPV's & Primers.

» Select Waxes to Obtain Desired Matting Effect in your Application

Effect of Wax on Black Heel Marks

Black heel marks occur in a floor coating when the heel or sole of a shoe leaves residue on the floor after a shoe scuffs or scrapes the coating surface. Grocery carts, platform trucks, hand trucks and fork lifts can all produce black marks.

By reducing the coefficient of friction of the coating, carefully selected waxes such as HDPE will have better mobility across a coating surface improving the heel mark resistance.

Thanks to its heel mark resistance property, wax emulsions are used in Floor Polish.

Applications of Wax Emulsions

Thanks to the various benefits discussed, wax emulsions are widely used in:

- Wood Coatings

- Concrete Coatings

- Metal Coatings

- Ink, OPV’s & Primers

- Architectural Coatings

- Plastic Coatings

- Paper, film & Foil Coatings

- Floor Polishes

Wood Coatings

Surface modifiers are added to wood stains and sealers to significantly improve the weatherability of exterior applications such as decks, rails, stairways and siding to:

With the proper use of a surface modifier, wood floor coatings (residential, commercial, and athletic facilities) can be protected from various degrees of traffic and wear during their lifetime, and can meet your VOC requirements. |  |

Wax emulsion formulations have been shown to reduce scratching, scuffing, marring, general wear and loss of gloss.

Concrete Coatings

Unprotected concrete in residential or commercial applications is susceptible to damage from many sources including the weather, equipment and vehicles, as well as humans.

|

|

Metal Coatings

Metal is used in the fabrication of many consumer and industrial products, from beverage cans to furniture to bridges. It is nearly always coated, firstly out of necessity to prevent the rapid effects of corrosion, but just as importantly to make the product more attractive. Surface modifiers enhance coating performance by a variety of functions, depending on the application.

Fixed structures such as bridges and industrial complexes require periodic coating maintenance to protect these valuable assets. Selective use of the appropriate wax surface modifier into the coating formula can provide:

- Water repellency (supplemental barrier properties),

- Mar and scratch protection, and

- Other functions

Ink, OPV's & Primers

The OPV's are most commonly water-based or UV-curable, with solvent-borne also used. Various types of wax-based slip/rub additives are formulated into all types of OPV. Proper selection of wax surface modifiers also depends on the end use of the printed media.

Wax surface modifiers are the essential additive to an ink formulation, providing slip control, rub resistance, and scratch resistance, all critical to maintaining the integrity of a graphic design.

Besides inks and OPV's, primers are sometimes used to prepare the media for printing. Primers enhance the ink receptivity of surfaces, improving ink adhesion, rub resistance, and image quality.

Architectural Coatings

Interior and exterior architectural applications present their own unique coating related problems.

|  |

Plastic Coatings

Plastics are coated for three main reasons: aesthetics touch/feel and wear resistance. Surface modifiers are also used in the recipe for lacquer coatings applied to plastic surfaces that require scratch & mar resistance, and even resistance to common products such as suntan oils, coffee and food stains.Paper, film & Foil Coatings

Flexible film packaging systems - often laminated with foil or paper - are increasingly popular and practical alternatives for packaging food and other goods. In the case of food, surface modifiers can again be incorporated into the film coating formulation to meet strict regulatory approvals for direct food contact.

Other special film performance attributes possible with wax surface modifiers include barriers to oxygen, moisture and grease, as well as heat sealability (preferably at low temperatures).

Floor Polish Coatings

Wax surface modifiers satisfy many of the performance demands of a floor polish. Proper selection and usage will control how the polish responds to buffing; minimize black heel marks; and provide slip control, i.e. the proper coefficient of friction to provide traction for foot traffic in wet or dry conditions.

By enhancing mar, scratch, and abrasion resistance, the surface modifier may also extend the durability of the polish, resulting in reduced maintenance demands.