OTHER LESSONS FROM H1N1

The 2009 H1N1 pandemic has also helped to promote non-alcohol hand sanitizer, specifically quat-based (Benzalkonium Chloride) hand sanitizers. This option is particularly useful in schools where there is a concern about children ingesting alcohol-based hand sanitizers.

"Prior to H1N1, there was a universal acceptance of alcohol-based sanitizers," says Linda Silverman, president at Maintex. "After that, you're seeing a greater understanding and acceptance of alcohol-free, quat-based hand sanitizers as well."

Quat-based hand sanitizers have a longer kill claim than alcohol-based varieties. It can still be effective against killing germs after it has been applied to the skin. Quat-based hand sanitizers are non-flammable and also don't dry hands out as much as alcohol-based products.

Hercules & Hercules Inc. sought to educate consumers on the benefits of quat-based sanitizers and encouraged school districts to make the switch.

"We provided samples and efficacy data," says Belinda Jefferson, company president. "Some made the switch, others didn't."

Along with the increase in hand sanitizer sales, distributors sold more foam hand soap following the H1N1 outbreak, thanks to the public's renewed interested in keeping hands clean. Hercules & Hercules encouraged salespeople to sell touch-free foam soap in addition to hand sanitizer and educate customers on the benefits of touch-free restrooms.

"Hand safety is something the public needs to be aware of," Jefferson says. "The most critical thing to do is to wash your hands."

Distributors also learned some valuable purchasing lessons from the pandemic, namely not to overlook any cross-contamination-related product when stocking up on the more obvious necessities, such as hand sanitizer and soap.

"H1N1 taught us to look at the whole picture when dealing with a pandemic," says Mike Griffin, sales manager at San-a-Care. "We probably could have given more thought to bringing in disposable gloves and masks because we got caught with orders for those, and we couldn't fill them very quickly."

lunes, 26 de julio de 2010

AFTER H1N1

WOOD FURNITURE CARE; BEST TIPS:

1. To clean the finish on your wood furniture just use warm water and mild dish soap. Cleaning furniture with water won't hurt it -- just be careful not to soak it. Use an old toothbrush for hard-to-get areas. Wipe the dirt off the surface with soft cloths or paper towels until they come up fairly clean. Then dry off any residual moisture with a soft cloth.

2. After a good cleaning, the best way to protect the finish is to use a good-quality soft paste wax. Apply a thin coat as directed on the label. Wait five minutes and buff lightly with a soft (shoe) brush or cloth. Wait another 30 to 60 minutes and buff/brush again with a bit more vigor. You'll see a beautiful shine return to the finish that will last for many months.

3. Keep your furniture out of the sun. The temperature of the summer sun coming through a window can go above 140 degrees. It will cook fine finishes, fading and destroying them over time, and dry out and shrink the wood, which will cause cracks.

4. Don't place wood furniture near heating units or vents. Dry heat will cause the wood to dry and shrink, leaving cracks. Use a humidifier in the drier months to bring the moisture up to the 40 to 45 percent level.

5. For a quick-fix touch up, use the appropriate color shoe polish on scratches and chips, especially to make them less visible on the feet of furniture. Carefully using a matching-color felt-tip marker first will hide it even better.

6. When polishing metal hardware, take it off the furniture first. Take your time and make a note to remember what piece goes back where. Use a quality metal polish to get it shining again. Once it's buffed, put it back on, being careful not to scratch the wood surfaces. I recommend that you don't try to do this all at one time. It can be a lot of work, so take a few days, doing a few pieces at a time, instead of getting tired and frustrated with trying to do too much.

7. Wood isn't hungry! You cannot feed furniture. No matter what the advertising says, wood cannot be fed or nourished or enriched with polishes or oils. Once it has a protective finish over it for beauty and protection, the wood is sealed. Polishes and oils will not penetrate it.

8. There are several ways to remove the white hazy ring or spot that the hot coffee mug or hot pizza box made on your table. The least invasive way is to rub it with a mild abrasive, such as non-gel toothpaste mixed with baking soda or cooking oil mixed with ashes. You can rub it in a small spot with your finger or use a soft cloth on larger areas.

Another method that has excellent results is to place a soft cloth or towel over the spot and iron it carefully for 10 to 20 seconds at a time with the iron at a medium setting. You can turn the iron up a bit if needed. Always keep the iron moving and check your progress frequently.

9. When shopping for new or antique furniture, look at the back, inside and undersides of furniture and drawers. Many times it tells you more about quality than looking at the "show" side. The so-called "secondary" woods can speak volumes about the age of the item and the quality of construction.

10. Restoring or refinishing an older or antique piece of furniture to its original glory might seem like a good idea, and many times it is. But it's important to get advice from someone who is knowledgeable about the item you are considering. You may find that your piece is valuable and just needs a proper cleaning. Any more extensive work should be left to a professional.

miércoles, 14 de julio de 2010

CLEANING OIL SPILLS , APPROPRIATE FOR THE GULF OIL !!

Cleaning and Salvaging: Video

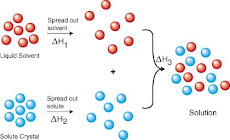

Two months after the massive oil spill in the Gulf of Mexico, a University of Pittsburgh, PA, engineering professor offers another cleanup solution. A cotton filter soaked in a polymer solution blocks oil and allows clean water to pass through. The polymer is both hydrophilic — so it bonds with the hydrogen in water, and oleophobic — so that it repels oil. The filter fabrication process entails soaking cotton cloth in liquid polymer solution followed by drying. The hope is to create trough-shaped filters to drag through the affected area, recovering oil and leaving clean water behind. A video shows impressive recovery; see: http://www.youtube.com/watch?v=kfRKjiOXVWE

martes, 6 de julio de 2010

OIL DISPERSANTS, TOXICITY as per EPA

EPA Releases First Round of Toxicity Testing Data for Eight Oil Dispersants

WASHINGTON —The US Environmental Protection Agency today released peer reviewed results from the first round of its own independent toxicity testing on eight oil dispersants. EPA conducted testing to ensure that decisions about ongoing dispersant use in the Gulf of Mexico continue to be grounded in the best available science.

EPA’s results indicated that none of the eight dispersants tested, including the product in use in the Gulf, displayed biologically significant endocrine disrupting activity. While the dispersant products alone – not mixed with oil - have roughly the same impact on aquatic life, JD-2000 and Corexit 9500 were generally less toxic to small fish and JD-2000 and SAF-RON GOLD were least toxic to mysid shrimp. While this is important information to have, additional testing is needed to further inform the use of dispersants.

"EPA is performing independent tests to determine the potential impacts of various dispersants. We will continue to conduct additional research before providing a final recommendation, " said EPA Administrator Lisa P. Jackson. "We want to ensure that every tool is available to mitigate the impact of the BP spill and protect our fragile wetlands. But we continue to direct BP to use dispersants responsibly and in as limited an amount as possible."

EPA continues to carefully monitor BP’s use of dispersant in the Gulf. Dispersants are generally less toxic than oil and can prevent some oil from impacting sensitive areas along the Gulf Coast. EPA believes BP should use as little dispersant as necessary and, on May 23, Administrator Jackson and then-Federal On-Scene Coordinator Rear Admiral Mary Landry directed BP to reduce dispersant usage by 75 percent from peak usage. EPA and the Coast Guard formalized that order in a directive to BP on May 26. Over the next month BP reduced dispersant use 68 percent from that peak.

Before directing BP to ramp down dispersant use, EPA directed BP to analyze potential alternative dispersants for toxicity and effectiveness. BP reported to EPA that they were unable to find a dispersant that is less toxic than Corexit 9500, the product currently in use. Following that, EPA began its own scientific testing of eight dispersant products on the National Contingency Plan Product Schedule (NCP-PS). Those dispersant products are: Dispersit SPC 1000, Nokomis 3-F4, Nokomis 3-AA, ZI-400, SAF-RON Gold, Sea Brat #4, Corexit 9500 A and JD 2000. Today’s results represent the first stage of that effort.

EPA tested these eight products for endocrine disrupting activity and potential impacts on small fish and mysid shrimp. The testing found:

· None of the eight dispersants tested displayed biologically significant endocrine disrupting activity.

· While all eight dispersants alone – not mixed with oil – showed roughly the same effects, JD-2000 and Corexit 9500 proved to be the least toxic to small fish, and JD-2000 and SAF-RON GOLD were the least toxic to the mysid shrimp.

The next phase of EPA’s testing will assess the acute toxicity of multiple concentrations of Louisiana Sweet Crude Oil alone and combinations of Louisiana Sweet Crude Oil with each of the eight dispersants for two test species.

To view the first round of test results please visit: http://www.epa.gov/bpspill/dispersants

R232

Vistas de página en total

GREEN CHEMICALS

Also the materials have to meet with toxicity and health requirements regarding inhalation, dermal and eye contact. There is also a specific list of materials that are prohibited or restricted from formulations, like ozone-depleting compounds and alkylphenol ethoxylates amongst others. Please go to http://www.greenseal.com/ for complete information on their requirements.

For information on current issues regarding green chemicals, see the blog from the Journalist Doris De Guzman, in the ICIS at: http://www.icis.com/blogs/green-chemicals/.

Certification is an important — and confusing — aspect of green cleaning. Third-party certification is available for products that meet standards set by Green Seal, EcoLogo, Energy Star, the Carpet & Rug Institute and others.

Manufacturers can also hire independent labs to determine whether a product is environmentally preferable and then place the manufacturer’s own eco-logo on the product; this is called self-certification. Finally, some manufacturers label a product with words like “sustainable,” “green,” or “earth friendly” without any third-party verification.

“The fact that there is not a single authoritative standard to go by adds to the confusion,” says Steven L. Mack M.Ed., director of buildings and grounds service for Ohio University, Athens, Ohio.

In www.happi.com of June 2008 edition, there is a report of Natural formulating markets that also emphasises the fact that registration of "green formulas" is very confused at present, due to lack of direction and unification of criteria and that some governmental instittion (in my opinion the EPA) should take part in this very important issue.